E-Grind produces high-quality Polycrystalline diamond composite(PDC) and polycrystalline diamond compact cutters.

E-Grind can provide a full range of diamond PDC with diameters ranging from 8mm to 19mm. And we can also provider polycrystalline diamond compact cutters which can be customized according to customer needs.

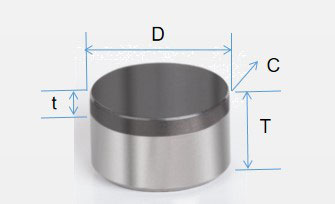

D+T is generally used to indicate product specifications

C is Diamond chamfer, the standard degree is 45°, 0.3 mm length.

Diamond table (t) thickness is 2.0 mm, 1.5 mm, 1.0mm.

Dimension can be customized according to customer needs

Available Spec for Oil/gas Grade

| D\T | 16 | 13 | 10 | 8 | 4 |

| 19 | * | • | * | * | o |

| 16 | * | • | * | • | o |

| 13 | o | • | * | • | • |

| 10 | o | o | • | • | • |

| 8 | o | o | o | • | • |

Available Spec for Mining Grade

| D\T | 16 | 13 | 10 | 8 | 4 |

| 19 | o | • | * | • | o |

| 16 | o | • | * | • | o |

| 13 | o | * | * | • | • |

| 10 | o | o | • | • | • |

| 8 | o | o | o | • | • |

| Note | |

| • | Available |

| o | NA |

| * | Customize |

|

|

|

|

Diamond Table The uniform micron size distribution, make PDC high bonding force and high density.Various particle sizes can meet customer needs for wear resistance and impact resistance demand. |

|

Interface We have various interface desgin to ensure optimal combination, |

|

Substrate E-Grind using 13% and 16% Co carbide substrate as standard specificaiton. Ensure the carbide substrate brazed strength to the drill bit body. |

Diamond-reinforced composite cutter are formed by sintering diamond particles and cemented carbide matrix at high temperature and pressure, which not only has the high wear resistance of diamond, but also has the high strength of cemented carbide. The products are widely used in roller cone bits, down-the-hole drill bits, picks, crushing machinery and other fields, and are the best substitute for cemented carbide cutter.

The diamond-reinforced composite cutter adopts the transition layer technology between the diamond layer and the cemented carbide layer, which has outstanding impact resistance and ultra-high wear resistance, making it widely used in high-end PDC bits, such as shock-absorbing cutter, Center cutter, gauge cutter, etc.

|

|

|

|

VTL |

|

|

Impact(Dye checking) |

|

|

C-Scan |

|

|

X-Ray |

|