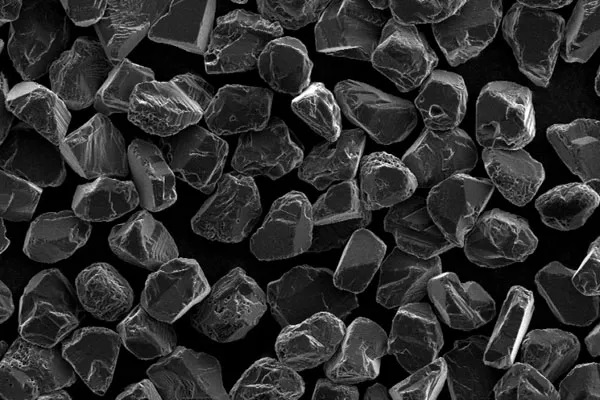

Sintering is a core process in producing high-quality CBN abrasive micron powder. During sintering, cubic boron nitride particles are subjected to high temperature and pressure, causing them to bond together without melting. This process forms a robust structure that enhances hardness, fracture toughness, and uniformity of the powder. Properly sintered CBN abrasive micron powder ensures consistent performance when used in polishing pads, cutting tools, or precision grinding applications. The sintering process must be carefully controlled to avoid particle deformation or unwanted phase transformations, which could compromise the material's abrasive efficiency and surface finish quality.

Classification is a crucial step that defines the particle size distribution and uniformity of CBN micron powder. For cbn powder for polishing pad exporters, controlling particle size ensures that the powder interacts predictably with polishing substrates, achieving optimal material removal rates and surface smoothness. Advanced classification techniques, such as air classification and precision sieving, are employed to separate particles into distinct size ranges. Uniform particle size not only improves polishing performance but also prevents premature wear of polishing pads, ensuring longer operational life and consistent results. Effective classification guarantees that every batch of CBN abrasive micron powder meets the stringent specifications required by international customers and high-precision industries.

The combination of sintering and classification directly affects the performance of CBN abrasive micron powder. Sintering defines the internal structure, hardness, and toughness of individual particles, while classification ensures that these particles are consistently sized for uniform application. Well-sintered and properly classified CBN powder produces even abrasion, reduces the risk of micro-scratches, and maximizes the efficiency of polishing and grinding processes. This is particularly important for applications in optical lens finishing, precision metal component polishing, and superhard material processing. Manufacturers like E-Grind ensure that sintering and classification are optimized together, resulting in powders that deliver predictable, high-quality performance across a wide range of industrial applications.

CBN abrasive micron powder is extensively used in polishing pads, cutting tools, and high-precision grinding applications. Its excellent hardness and wear resistance make it ideal for finishing hard metals, alloys, and ceramics. In polishing pads, uniform CBN micron particles provide smooth and controlled material removal, producing scratch-free surfaces essential for optical, automotive, and electronics components. In grinding applications, CBN abrasive micron powder ensures consistent cut rates and maintains dimensional accuracy of tools and parts. The synergy between sintering and classification allows manufacturers to offer cbn powder for polishing pad exporters with predictable performance, enabling end-users to achieve optimal polishing quality, reduce downtime, and maintain high productivity.

Ensuring consistent quality in CBN abrasive micron powder production requires rigorous quality control measures throughout both sintering and classification stages. Particle morphology, size distribution, and hardness are closely monitored using advanced analytical techniques. Each batch undergoes inspection to verify uniformity, ensuring that the powder performs reliably in polishing pads or precision grinding applications. By adhering to strict quality standards, manufacturers can deliver cbn powder for polishing pad exporters that meets the requirements of international markets. This attention to detail guarantees that the final products provide uniform material removal, enhanced surface finish, and long-lasting performance in industrial applications.