E-Grind supplies the whole range of PCD blanks and PCDN blanks for cutting tool purpose. The largest Diameter of PCD blanks and PCDN blanks available can be 55mm. Our PCD blanks and PCDN blanks provide high wearing resistance ability and high finishing surface.

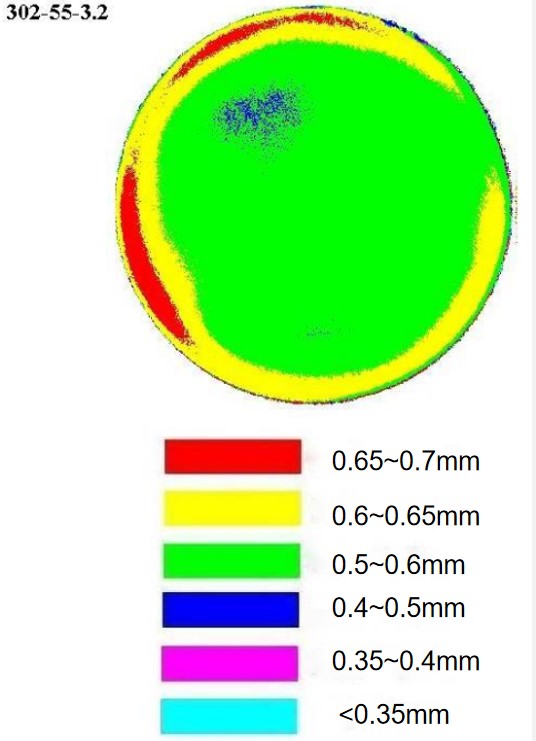

Our plant installs laser cutting machines and surface lapping and finishing machines to provide full service for PCD. With advanced inspecting machines of SEM, C-SCAN, X-Ray Diffractometer etc. Our plant applies strict Quality Control process.

Non-ferrous metals and alloys: Aluminum/gray iron composite, copper, Aluminum...

Nonmetallic materials: ceramics, plastic, rubber, chipboard...

| Product | Diamond Content (Vol%) | Product Properties | Application | |||

| ET02 | ≥92 | Very good electrical discharge machining, general life, better heat resistance and impact resistance. | Superfinishing, excellent surface processing quality for copper, bronze, aluminum, magnesium, magnesium aluminum alloy, plastic, precious metals, etc. | |||

| ET05 | ≥92 | Very good electrical discharge machining, general life, better heat resistance and impact resistance. | Superfinishing, excellent surface processing quality for copper, bronze, aluminum, magnesium, magnesium aluminum alloy, plastic, plexiglass, etc. | |||

| ET10 | ≥95 | Good electrical discharge machining, long life, better heat resistance and impact resistance. | Fine machining, very good surface processing quality, for aluminum alloy (Si content<12%), copper alloy, composite wood processing, high-precision wear-resistant corbelled device, etc. | |||

| ET25 | ≥95 | Good electrical discharge machining, long life, better heat resistance and impact resistance. | Used for composite, laminate flooring, nonmetal hard and brittle materials, carbide alloy, graphite and graphite composites, aluminum silicon alloy (Si content>12%), the other high wear-resistant materials, such as ceramics, carbide, etc. | |||

| ET35 | ≥95 | Good electrical discharge machining, very long life, good heat resistance and impact resistance. | Used for resin, composite materials, fiber reinforced plastics, high density reinforced board, silicon aluminum alloy and other high wear-resistant materials. | |||

| ET302 | ≥95 | Good electrical discharge machining, long life, better heat resistance and impact resistance. | Used for composite, laminate flooring, nonmetal hard and brittle materials, carbide alloy, graphite and graphite composites, aluminum silicon alloy (Si content>12%), the other high wear-resistant materials, such as ceramics, carbide, etc. | |||

| Grain size | Application | Grade | Diameter | Total thickness | DIamond table thickness | Woodworking | Metalworking | Conductive |

| 0.85μm | Ultra-fine micron structure for excellent surface finish requirements, | ET085 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | ||

| 55 | 1.6/2.0/3.2 | 0.5±0.15 | √ | |||||

| 2μm | For good surface finishing | ET02 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5±0.15 | √ | |||||

| 5μm | ET05 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | √ | |

| 10μm | General purpose, balance cutting efficiency and life | ET10 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | ||||

| 25μm | Good wear resistance production,for high Si% Al alloy. | ET25 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | √ |

| 55 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | ||||

| 302μm | ET302 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | √ | |

| 55 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | ||||

| 35μm | ET35 | 45 | 1.6/2.0/3.2 | 0.5±0.15 | √ | √ | ||

| 55 | 1.6/2.0/3.2 | 0.5±0.15 | √ |

PCBN consists of CBN and Binder. It is produced in high pressure and high temperature. It has excellent performance in hardness, wearing resistance, thermal stability.

Application: for hard ferrous materials such as hardened steel, cast iron, high-temperature alloy, HSS, powder metallurgy metals, Ni-Cr alloy, etc. The processed PCBN blank is widely used for high-speed and high-precision machining.

E-Grind provides two series of PCBN:

1) Solid CBN

2) CBN with Tungsten Carbide supporting.

PCBN and SBN Grade

| Grade | CBN grit (μm) | CBN content (Vol%) | Processing way | Application |

| SBN95Z1 PCBN95Z1 | 20、30 | 0.95 | Continuous cutting with large stock removal | For Rough processing Grey Cast Iron, Chilled Cast Iron, Powder Sintered Alloy. |

| SBN90Z PCBN90Z | 10、15 | 0.9 | Continuous cutting with large stock removal | For Rough process and semi-finishing processing the wear resistant cast iron, nodular cast iron etc. |

| SBN90Z2 PCBN90Z2 | 10、15 | 0.9 | Continuous cutting with large stock removal | For rough processing and semi-processing alloy cast iron, high nickel Chrome, high chrome iron and chilled steel with hardness HRC45-50. |

| SBN80G | 3、5 | 0.8 | Continuous cutting with Medium stock removal | For rough processing and semi-processing alloy cast iron, high nickel Chrome, high chrome iron and chilled steel with hardness HRC45-50. |

| SBN70G PCBN70G | 3、5 | 0.7 | Continuous cutting with small stock removal | For finishing the chilled steel and high temperature alloy with HRC45-55. |

| SBN60G | 1、3 | 0.6 | Continuous cutting with small stock removal | For finishing and super-finishing the chilled steel with HRC55-62 like bearing steel, tool steel, mold steel, gauge steel and HSS. |

| SBN55G1 PCBN55G1 | 1、3 | 0.55 | Slight non-continuous and continuous cutting with small stock removal | For Finishing and super-finishing the chilled steel with HRC55-65, like bearing steel, tool steel, mold steel, gauge steel and HSS. |

| SPEC | D(Diameter) (mm) | T(Thickness)(mm) | t (CBN section thickness)(mm) | PCBN55G1 | PCBN70G | PCBN90Z | PCBN90Z2 | PCBN95Z1 |

| Ф45×1.2×0.6 | 45 | 1.2±0.05 | 0.5-0.8 | √ | √ | √ | √ | √ |

| Ф45×1.6×1.0 | 45 | 1.6±0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45×3.2×1.0 | 45 | 3.2±0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45×3.8×1.0 | 45 | 3.8±0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

| Ф45×4.5×1.0 | 45 | 4.5±0.05 | 0.9-1.2 | √ | √ | √ | √ | √ |

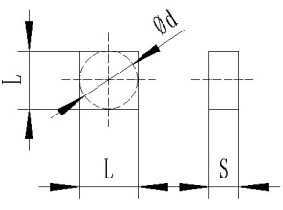

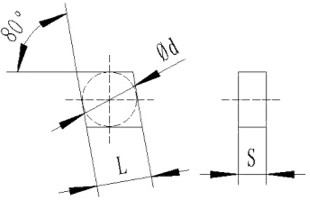

| Spec | Dimension (mm) | ISO | Code | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 9.85×3.4 | 9.85 | 9.85 | 3.4 | SNMN090300 | √ | √ | √ | √ | √ | √ | √ |

| 9.85×5 | 9.85 | 9.85 | 5 | SNMN090400 | √ | √ | √ | √ | √ | √ | √ |

| 13×5 | 13 | 13 | 5 | SNMN120400 | √ | √ | √ | √ | √ | √ | √ |

| 16.2×8.2 | 16.2 | 16.2 | 8.2 | SNMN150700 | √ | √ | √ | √ | √ | √ | √ |

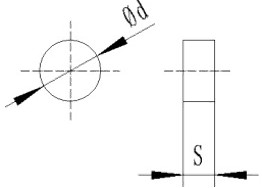

| Spec | Dimension (mm) | ISO | Code | ||||||||

| Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | |||

| 6.7×5 | 6.7 | 5 | RNMN060400 | √ | √ | √ | √ | √ | √ | √ | |

| 9.85×3.4 | 9.85 | 3.4 | RNMN090300 | √ | √ | √ | √ | √ | √ | √ | |

| 9.85×5 | 9.85 | 5 | RNMN090400 | √ | √ | √ | √ | √ | √ | √ | |

| 13×5 | 13 | 5 | RNMN120400 | √ | √ | √ | √ | √ | √ | √ | |

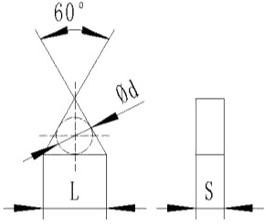

| Spec | Dimension(mm) | ISO | Code | |||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | ||

| 9.85×5 | 9.85 | 9.85 | 5 | CNMN090400 | √ | √ | √ | √ | √ | √ |

| 13×5 | 13 | 13 | 5 | CNMN120400 | √ | √ | √ | √ | √ | √ |

| 13×8.2 | 13 | 13 | 8.2 | CNMN120800 | √ | √ | √ | √ | √ | √ |

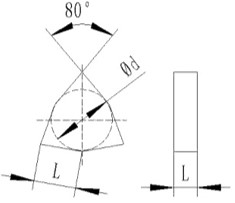

| Spec | Dimension(mm) | ISO | Code | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 11.3×3.4 | 11.3 | 6.524 | 3.4 | TNGN110300 | √ | √ | √ | √ | √ | √ | √ |

| 16.8×5 | 16.8 | 9.699 | 5 | TNGN160400 | √ | √ | √ | √ | √ | √ | √ |

| Spec | Dimension (mm) | ISO | Code | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 9×5 | 9 | 13.1 | 5 | WNMN080400 | √ | √ | √ | √ | √ | √ | √ |

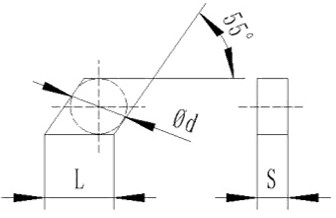

55° Rhombus

| Spec | Dimension (mm) | ISO | Code | ||||||||

| L | Фd | S | SBN55G1 | SBN60G | SBN70G | SBN80G | SBN90Z | SBN90Z2 | SBN95Z1 | ||

| 11.3×5 | 11.3 | 9.256 | 5 | DNUN110400 | √ | √ | √ | √ | √ | √ | √ |

| 11.3×6.6 | 11.3 | 9.256 | 6.6 | DNUN110600 | √ | √ | √ | √ | √ | √ | √ |

| 15.8×6.6 | 15.8 | 12.943 | 6.6 | DNUN150600 | √ | √ | √ | √ | √ | √ | √ |