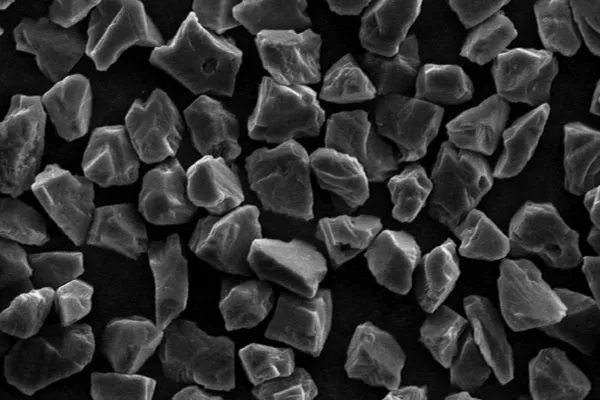

Synthetic diamond powders are engineered to deliver exceptional hardness, thermal conductivity, and chemical stability, making them ideal for a wide range of industrial applications. These powders are produced under controlled conditions to achieve uniform particle size, shape, and purity, ensuring consistent performance in grinding, polishing, and lapping operations. The precise structure of synthetic diamond powders allows them to efficiently remove material from even the hardest surfaces, while maintaining high surface quality. Their resistance to wear and thermal degradation ensures reliability during continuous operation, which is critical in applications requiring both precision and durability.

The use of synthetic diamond powders directly enhances the efficiency and quality of machining and polishing processes. Fine particle sizes provide smoother finishes and reduced surface roughness, while coarser particles allow for faster material removal in rough grinding operations. In polishing optical lenses, semiconductors, and hard metals, synthetic diamond powders ensure uniform abrasion, reducing the likelihood of micro-scratches or surface defects. Their consistent performance minimizes variability between production batches, allowing manufacturers to achieve precise tolerances and superior surface finishes repeatedly. These qualities make synthetic diamond powders indispensable in industries where high-precision surfaces are critical.

Synthetic diamond powders are widely used in electronics, aerospace, automotive, optics, and tooling industries. In electronics manufacturing, they enable precise shaping and polishing of components such as wafers and connectors. In aerospace and automotive sectors, these powders facilitate the machining of high-strength alloys and composites. In tooling applications, they are employed to coat or impregnate cutting, grinding, and drilling tools, significantly extending tool life while maintaining performance. The versatility of synthetic diamond powders allows them to meet the demands of both high-speed industrial operations and meticulous finishing processes, ensuring reliable results across multiple applications.

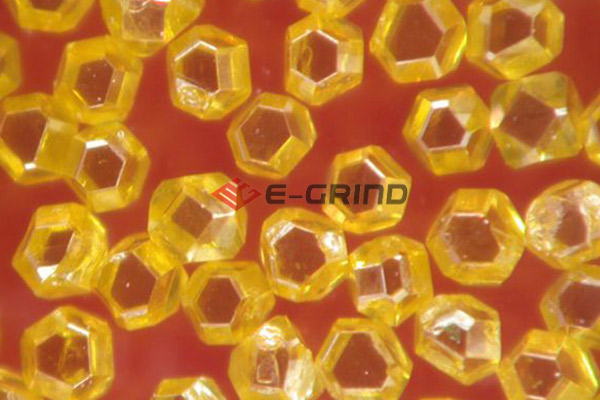

The preference for synthetic diamond powders arises from their unique combination of hardness, purity, and controllable particle morphology. Unlike natural diamonds, synthetic powders can be engineered to specific specifications, allowing precise control over particle size distribution and crystal shape. This enables manufacturers to optimize their processes for either aggressive material removal or delicate surface finishing. Additionally, their chemical stability ensures that they remain inert even under high temperatures or in the presence of reactive substances, providing consistent performance without degradation. These characteristics establish synthetic diamond powders as the material of choice for demanding precision applications.

Synthetic diamond powders deliver exceptional performance across a wide range of industrial operations. Their hardness and uniform particle structure allow them to efficiently remove material from both soft and extremely hard surfaces while maintaining precise control over the cutting or polishing process. In optical lens finishing, semiconductor wafer polishing, and high-precision metal machining, these powders provide consistent surface smoothness and minimal micro-scratches. They are also effective in high-speed grinding and lapping operations, enabling faster processing rates without compromising surface quality. The versatility and durability of synthetic diamond powders make them an essential component for achieving superior results in demanding industrial applications.