Metal bond micron diamond powder is widely used in precision grinding and polishing applications due to its exceptional hardness, thermal stability, and wear resistance. To ensure consistent performance in industrial environments, rigorous testing methods are essential. Testing not only verifies the particle size distribution and morphology but also assesses the bonding strength of the metal matrix with the diamond particles. Proper testing guarantees that the powder maintains uniform abrasive properties during high-speed or high-load operations, enabling predictable material removal rates and superior surface finishes. Consistency in these characteristics is critical for industries such as automotive, aerospace, electronics, and tool manufacturing, where precision and reliability are paramount.

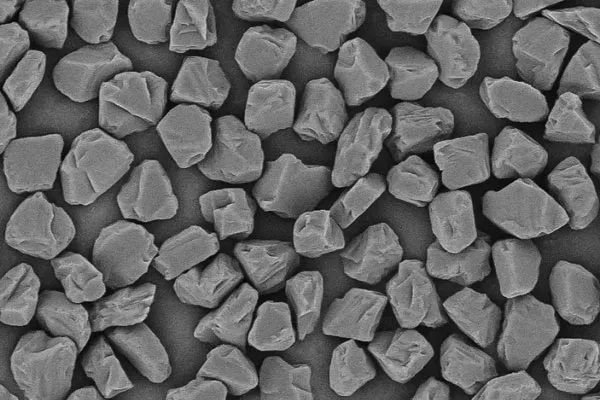

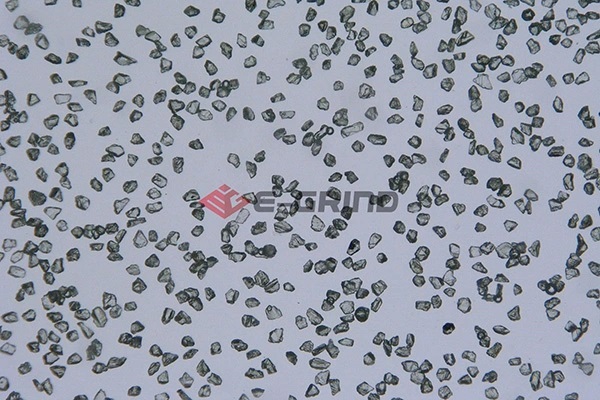

Testing metal bond micron diamond powder improves its performance by identifying variations in particle size, shape, and distribution, which directly influence the efficiency of grinding and polishing processes. Techniques such as laser diffraction, scanning electron microscopy (SEM), and particle imaging allow manufacturers to monitor particle uniformity and detect irregularities. These tests ensure that each batch of metal bond micron diamond exhibits predictable behavior in industrial applications. Additionally, hardness and wear resistance tests simulate operational conditions, verifying that the powder can withstand high mechanical and thermal stresses. By understanding the results of these tests, engineers can optimize the powder for specific applications, achieving consistent removal rates and improved surface quality.

Characterizing the chemical composition and physical properties of metal bond micron diamond is essential for quality assurance. X-ray fluorescence (XRF) and energy-dispersive X-ray spectroscopy (EDS) are commonly used to analyze the elemental composition and confirm that the metal binder content aligns with specifications. Physical characterization includes measuring particle hardness, density, and porosity, which affect the powder's performance during grinding or lapping operations. By combining chemical and physical analysis, manufacturers ensure that the metal bond micron diamond has the optimal balance of toughness and abrasive effectiveness. This integrated testing approach prevents inconsistencies that could lead to premature tool wear or uneven surface finishes.

Practical performance testing of metal bond micron diamond powder involves simulating real-world industrial conditions. This may include using the powder in test grinding wheels, polishing pads, or lapping machines under controlled load and speed conditions. Surface roughness measurements, material removal rates, and wear monitoring provide quantitative data on the powder's effectiveness. By correlating these results with laboratory measurements, engineers can confirm that the metal bond micron diamond performs reliably in its intended application. Testing in situ ensures that the powder delivers both efficiency and consistency, supporting high-precision operations in automotive component finishing, optical polishing, and cutting tool maintenance.

Advanced testing methods are essential for ensuring long-term quality and consistency of metal bond micron diamond powder. By routinely applying particle size analysis, morphology examination, hardness testing, and performance evaluation, manufacturers can maintain high standards across production batches. Consistent testing minimizes variability, enabling end-users to achieve superior surface finishes and reliable tool performance. With these rigorous quality checks, metal bond micron diamond continues to provide unmatched precision, wear resistance, and stability, making it a trusted choice for industrial applications where accuracy and efficiency are critical.