As a leading expert in diamond and CBN abrasives, E-Grind Abrasives delivers high-performance polycrystalline diamond powder (PCD) to industries demanding precision and reliability. With over 50 years of experience, we ensure exceptional product consistency through advanced manufacturing and strict quality control. Our polycrystalline diamond powder is widely used in sawing, grinding, lapping, and polishing applications, meeting the highest industrial standards.

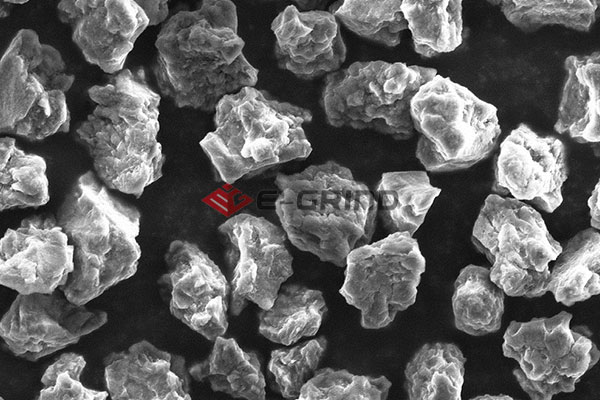

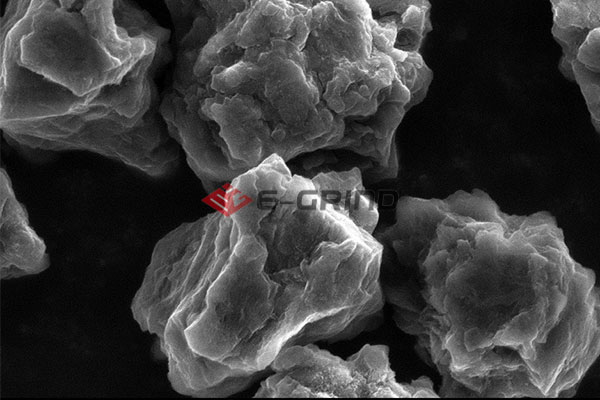

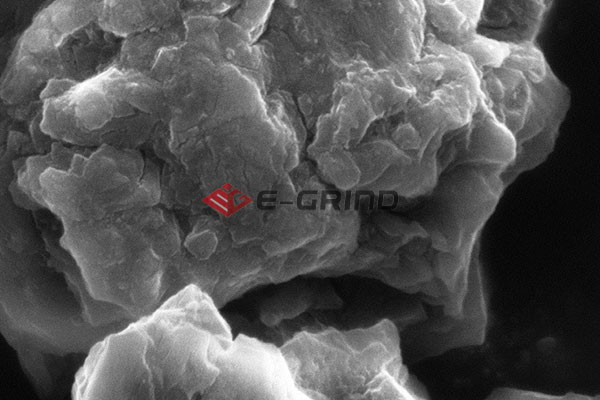

Polycrystalline diamond powder stands out as a superior abrasive due to its unmatched hardness, wear resistance, and self-sharpening properties. Unlike conventional abrasives, PCD consists of micron-sized diamond crystals bonded together, delivering:

Longer lifespan: The interconnected diamond grains continuously expose fresh cutting edges, ensuring sustained abrasive performance.

Superior surface finish: Ideal for high-precision semiconductor wafer polishing and optical lens grinding, minimizing micro-scratches.

Thermal stability: Maintains cutting efficiency even under extreme machining conditions, reducing heat-induced defects.

By choosing E-Grind Abrasives' polycrystalline diamond powder, manufacturers optimize efficiency while maintaining strict tolerances and superior surface quality.

Features | Polycrystalline Diamond Powder | Monocrystalline Diamond Powder |

Structure | Multiple fused diamond grains | Single-crystal diamond particles |

Wear Resistance | Excellent (self-sharpening) | Good (but wears as a whole) |

Applications | Heavy grinding, lapping, optics | Ultra-fine polishing, engraving |

While monocrystalline diamond powder excels in ultra-precision tasks, polycrystalline diamond powder (PCD) is the preferred choice for industrial-scale machining due to its durability and cost-effectiveness.

Leading industries—including semiconductors, aerospace, and optics—trust polycrystalline diamond powder because:

Consistent Performance: E-Grind Abrasives' strict quality control ensures uniform particle size, crucial for repeatable machining results.

Reduced Downtime: PCD's self-regenerating structure minimizes abrasive replacement frequency.

Broad Applicability: Efficiently processes tungsten carbide, ceramics, and silicon wafers with minimal surface damage.

Our fully traceable manufacturing process guarantees that every batch meets exacting standards, reinforcing why PCD remains the top-performing abrasive for high-tech applications.

Choosing the right polycrystalline diamond powder is critical for achieving optimal machining results. Consider the following factors:

Particle Size Distribution: E-Grind Abrasives offers micron-level grading for precise material removal control.

Purity & Contaminants: High-quality PCD should have minimal impurities to avoid surface defects.

Application-Specific Grades: Coarser grits for heavy grinding; finer grits for mirror polishing.

At E-Grind Abrasives, we provide technical consulting to help manufacturers select the ideal PCD for their specific needs, ensuring maximum productivity and cost savings.

With a corporate philosophy rooted in professionalism, integrity, and customer focus, E-Grind Abrasives continues to be a reliable partner in abrasive solutions. Our polycrystalline diamond powder is engineered for exceptional precision, durability, and efficiency, making it the first choice for industries where quality and performance are non-negotiable.