As a leader in high-performance abrasive solutions, E-Grind Abrasives has been supplying industrial-grade polycrystalline diamond powder to manufacturers worldwide, delivering unmatched cutting and polishing capabilities for the most demanding applications. Unlike conventional abrasives, our polycrystalline diamond powder consists of multiple diamond crystallites bonded together, creating a material that combines exceptional hardness with superior durability.

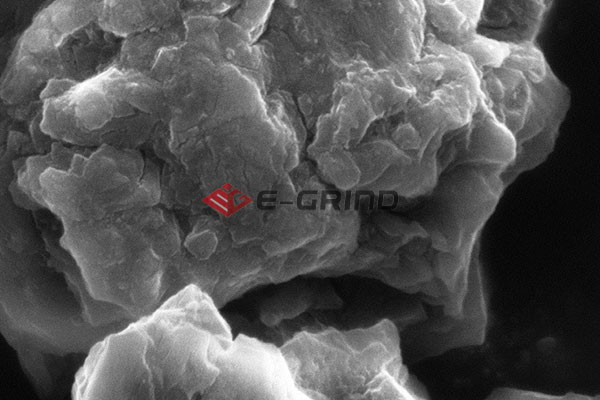

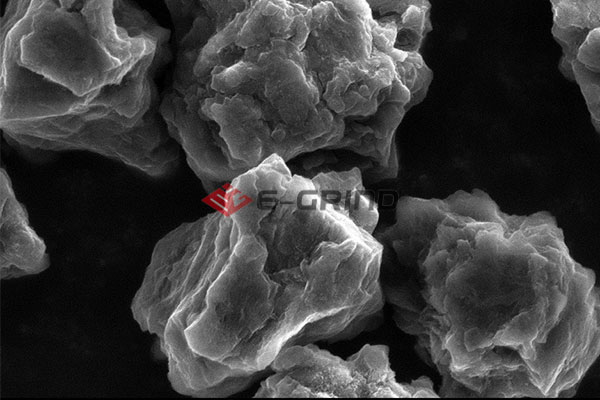

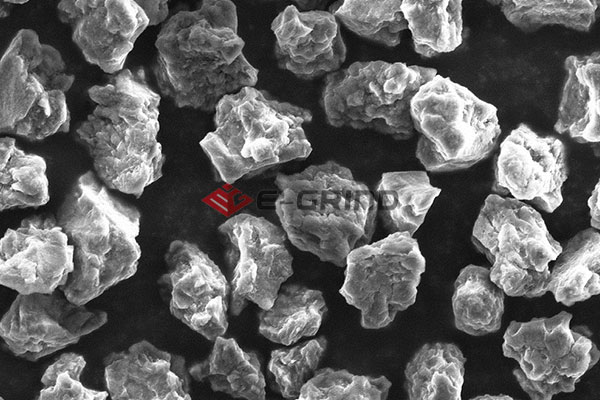

Polycrystalline diamond powder represents a significant advancement in abrasive technology, composed of numerous tiny diamond crystals fused into tough, intergrown structures. At E-Grind Abrasives, we produce this premium material through advanced high-pressure, high-temperature (HPHT) synthesis, resulting in a powder that exhibits uniform particle distribution and consistent performance. The polycrystalline nature of this diamond powder gives it unique fracture characteristics - when individual crystals wear or break, fresh cutting edges are continuously exposed, maintaining abrasive efficiency throughout the machining process.

When evaluating polycrystalline diamond powder against traditional monocrystalline alternatives, several critical distinctions emerge. While both materials feature extreme hardness, the polycrystalline structure offers superior fracture resistance and longer service life in aggressive machining operations. The intergrown crystals in polycrystalline powder create self-sharpening properties absent in single-crystal diamond, where entire particles can be lost during use. Monocrystalline diamond may provide a sharper initial cut for ultra-precision applications, but polycrystalline diamond powder demonstrates better performance retention in most industrial grinding, lapping and polishing operations where consistent results matter most.

E-Grind Abrasives' polycrystalline diamond powder has become indispensable in advanced machining processes that demand extreme precision and material removal efficiency. The powder excels in grinding hard materials like tungsten carbide, ceramics, and optical glass where conventional abrasives fail prematurely. Its unique structure allows for controlled material removal without excessive subsurface damage, making it particularly valuable for semiconductor wafer processing and high-value component manufacturing. Manufacturers worldwide trust our carefully graded powder sizes to achieve the exact surface finishes required for their most critical components.

Beyond cutting applications, polycrystalline diamond powder serves as the abrasive of choice for achieving mirror finishes on challenging materials. The powder's multi-faceted crystals provide numerous cutting edges that produce exceptionally smooth surfaces free from the scratching often associated with other abrasives. E-Grind Abrasives supplies specialized formulations for polishing sapphire substrates, silicon wafers, and high-performance bearing components where surface perfection directly impacts product performance. Our technical team works closely with clients to recommend the optimal particle size distribution for their specific finishing requirements.

The versatility of polycrystalline diamond powder extends to numerous niche industrial applications where conventional abrasives prove inadequate. Diamond powder compounds enhance the performance of wire drawing dies, improve the efficiency of cutting tools, and extend the life of precision measurement equipment. E-Grind Abrasives provides custom-formulated blends for specialized uses in the aerospace, defense, and medical device industries, where material performance directly impacts safety and reliability. Our powders also serve as key components in advanced superabrasive tools and wear-resistant coatings.

With decades of expertise in abrasive material science, E-Grind Abrasives continues to innovate in polycrystalline diamond powder technology to meet the evolving needs of precision manufacturers. We maintain rigorous quality control standards to ensure consistent particle size distribution and performance characteristics in every batch. By combining technical knowledge with responsive customer service, we help manufacturers optimize their processes with the most effective abrasive solutions available. As materials become harder and tolerances tighter in modern industry, polycrystalline diamond powder remains at the forefront of abrasive technology, delivering performance that conventional materials cannot match.