As a trusted supplier of high-performance abrasives, E-Grind Abrasives has been at the forefront of advanced material solutions, providing industry-leading polycrystalline diamond powder (PCD) for precision applications. In the demanding fields of semiconductor and optical manufacturing, polycrystalline diamond powder has emerged as a game-changing abrasive, enabling unprecedented levels of precision, efficiency, and cost-effectiveness.

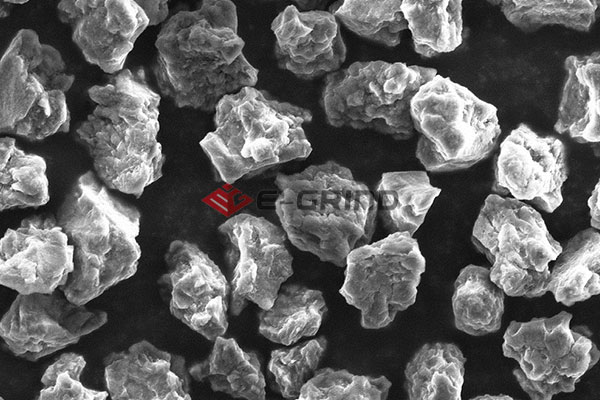

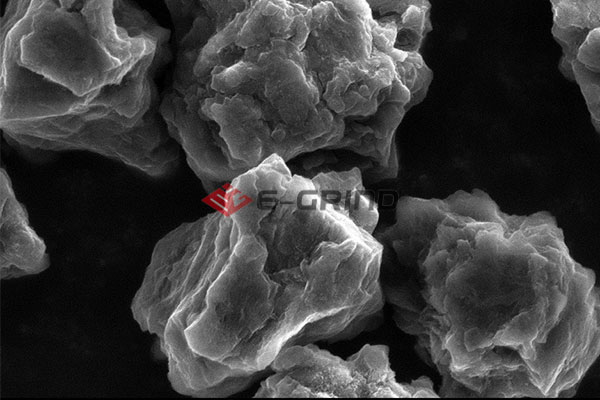

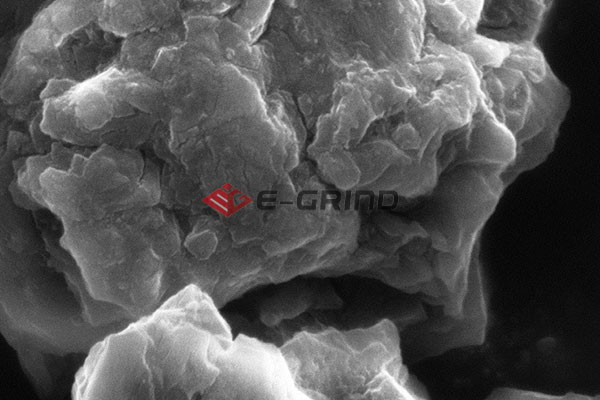

The polycrystalline diamond powder supplied by E-Grind Abrasives plays a crucial role in semiconductor fabrication, particularly in wafer thinning, dicing, and polishing. Unlike conventional abrasives, polycrystalline diamond powder consists of micron-sized diamond crystallites fused together, creating a material with superior hardness and fracture resistance. This allows semiconductor manufacturers to achieve ultra-precise material removal without inducing micro-cracks or subsurface damage—a critical requirement for next-generation microchips and integrated circuits.

When comparing polycrystalline diamond powder to monocrystalline alternatives, several key factors come into play. Monocrystalline diamond powder consists of single-crystal structures, offering extremely sharp cutting edges but lower toughness. In contrast, polycrystalline diamond powder features multiple interconnected grains, providing a self-sharpening effect—as one crystal fractures, new cutting edges are exposed, ensuring prolonged abrasive performance. This makes polycrystalline diamond powder especially advantageous for optical glass polishing, where consistent surface quality and minimal defects are paramount.

The optical industry demands surfaces with nanometer-level smoothness, free from scratches or defects that could distort light transmission. E-Grind Abrasives supplies high-purity polycrystalline diamond powder tailored for lapping and polishing lenses, mirrors, and laser optics. The powder's uniform particle distribution and durable crystal structure enable controlled material removal, resulting in optically perfect finishes. Manufacturers of high-end camera lenses, telescopes, and laser systems rely on polycrystalline diamond powder to achieve the stringent surface quality required for advanced optical systems.

Semiconductor wafers require extreme thinning to meet the demands of modern microelectronics. Polycrystalline diamond powder is widely used in wafer backgrinding processes, where its exceptional wear resistance ensures consistent material removal without causing excessive heat or stress. Compared to traditional silicon carbide or alumina abrasives, polycrystalline diamond powder significantly reduces processing time while maintaining superior dimensional control, minimizing warpage, and extending the lifespan of grinding wheels.

As semiconductor nodes shrink and optical components become more intricate, the need for high-performance abrasives continues to rise. E-Grind Abrasives is committed to advancing polycrystalline diamond powder technology to meet these evolving challenges. Emerging applications in 5G chips, augmented reality (AR) lenses, and quantum computing components further highlight the material's critical role in cutting-edge manufacturing.

By leveraging E-Grind Abrasives' expertise in polycrystalline diamond powder, manufacturers in the semiconductor and optical industries gain access to a superior abrasive solution that enhances precision, reduces waste, and improves production efficiency. The unique properties of polycrystalline diamond powder make it indispensable in applications where only the highest performance will suffice, reinforcing its status as a revolutionary material in high-tech manufacturing.