1. Introduction of PCD tool

As a superhard tool material, diamond has been widely used in cutting. The high price of natural diamond has restricted the development of diamond tools. In the 1970s, people used high-pressure synthesis technology to synthesize Polycrystalline diamond (PCD), which solved the scarcity of natural diamond The problem of high price makes the application range of diamond tools extend to aviation, aerospace, automobile, electronics, stone and other fields.

Polycrystalline diamond (PCD) tools are mainly used to process non-ferrous metals such as non-ferrous metals, can sharpen the sharp edges, get a better processing surface, and are also the first choice for processing non-metallic new materials. And industrial ceramics and other high-hardness products.

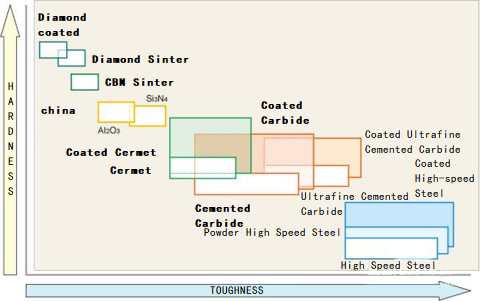

Comparison Chart of Hardness and Toughness of PCD Tools and Other Tool Materials

2. Performance advantages of PCD tools

1) The hardness of PCD can reach 8000HV, which is 80 ~ 120 times that of cemented carbide, and the wear resistance of PCD is better.

2) The thermal conductivity of PCD is 700W / MK, which is 1.5-9 times that of cemented carbide, even higher than PCBN and copper. Therefore, the heat transfer of the PCD tool is rapid, and good heat transfer can extend the tool life to a large extent.

3) The friction coefficient of PCD is generally only 0.1 to 0.3, while the friction coefficient of cemented carbide is 0.4 to 1. Therefore, PCD tools can significantly reduce cutting forces, thereby extending tool life.

4) The thermal expansion coefficient of PCD is small, so the thermal deformation of PCD tools is small, and the processing accuracy is high. The greater the thermal deformation of the tool, the worse the surface quality of the processed workpiece. To process a workpiece with a good surface quality, the thermal deformation of the tool must be strictly controlled.

5) The affinity of

PCD cutters with non-ferrous and non-metallic materials is small, and the cutting edge is not easy to form a built-up edge during the machining process. The affinity of the tool and the material to be processed is small, so the material to be processed is not easy to adhere to the surface of the tool during the processing process, and it is not easy to form a built-up edge.

6) The PCD tool has a large elastic modulus, high fracture strength (three times higher than alumina), the cutting edge blunt radius value can be ground very small, it is not easy to break, and it can maintain the sharpness of the cutting edge for a long time.

3. The structure of PCD cutter

Polycrystalline diamond (PCD) cutters are cutters made by welding PCD composite sheets to carbide or steel cutter bodies. Because the PCD composite sheet combines the high hardness, wear resistance, low friction coefficient and strength of single crystal diamond with the high bending strength of tungsten carbide cemented carbide, the tungsten carbide cemented carbide layer of the composite sheet provides the diamond layer The mechanical support increases its flexural strength, and at the same time the carbide layer is easy to weld, making it easy to make finished tools.

The structure of PCD tools are: PCD inserts, PCD milling cutters, PCD reamers, PCD drill bits, PCD grooving cutters, non-standard PCD cutters.

4. Processing material of PCD tool

1) Difficult to process non-ferrous metals and their alloy materials When processing non-ferrous metals such as copper, zinc, aluminum and their alloys, sintered hard alloys, titanium alloys, and pasteurized alloys, the materials tend to stick to the tool, and the processing is difficult. The metal is bonded to the tool and the tool has a long service life. For titanium alloys, copper alloys, tungsten carbide cemented carbides (Co <16% and Co> 16%), aluminum alloys (4-8% Si and 9-13% Si), high-silicon aluminum alloys (> 13% Si) , CDW010 grade PCD cutters are applicable. For alloy materials with higher wear resistance requirements, coarse-grained and mixed-grained PCD cutters CDW025 and CDW302 can be used. 2) Difficult to process non-metallic materials, such as glass fiber reinforced plastics, silicon-filled materials, hard carbon fiber / epoxy composite materials, ceramics, wood, serious tool wear, difficult to process, PCD tools have high hardness and good wear resistance, High processing efficiency, commonly used PCD materials are CDW010, CDW025 and CDW302.

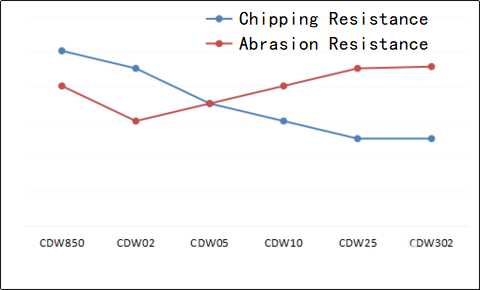

5. The performance of PCD tool material grade

In addition to the structure of conventional PCD tools, PCD chipbreaker blades, PCD milling blades and non-standard PCD tools can be customized.

Application conditions and processing characteristics of

PCD material grades

|

|

Grain Size

|

Properties

|

Application

|

|

CDW850

|

sub-micron

|

Ultra-fine grain structure has extremely strong edge sharpness and edge durability

|

Ultra-high precision machining, high mirror surface machining, suitable for milling and rough cutting of aluminum alloys with extremely high chipping requirements, mainly used for machining titanium alloys and composite materials

|

|

CDW002

|

2μm

|

Higher cobalt content, good electrical processing performance, toughness and surface finish of the processed workpiece, which is convenient for processing of complex tools

|

It is mainly used in the processing of routers and thread cutting tools for forming, and it can also be used in the processing of wear-resistant parts for wood chipboard, saw blades, silicon aluminum alloy, and power tool saw blades.

|

|

CDW005

|

5μm

|

Excellent EDM and machining performance, good toughness, wear resistance and cutting edge quality

|

It is suitable for high-finish surface finishing, mainly used in the processing of plexiglass, silicon aluminum alloy, metal mobile phone shell contours, etc., and used in the processing of woodworking forming knives and saw blades.

|

|

CDW010

|

10μm

|

Universal type, taking into account good toughness and high wear resistance

|

It is suitable for the rough and fine cutting of a single tool. It is especially suitable for woodworking molding, low and medium silicon aluminum alloy parts (such as pistons).

|

|

CDW025

|

25um

|

Extremely high wear resistance and cutting edge quality

|

It is more suitable for processing high-silicon aluminum alloy, metal matrix composite (MMC) cemented carbide and ceramics, graphite and other brittle and hard materials. It is suitable for processing woodworking trimming knives, wear-resistant parts, woodworking calcium sulfate, and saw blades.

|

|

CDW302

|

2~30μm

|

The mixed particle size of 2μm and 5μm has excellent wear resistance, edge strength and edge quality

|

Applications include metal matrix composites (MMC), high-silicon aluminum alloy gold, high-strength cast iron and bimetallic applications.

|

6. Selection of PCD tools

The main considerations for the selection of PCD tools: surface accuracy, shape accuracy, dimensional accuracy, tool deformation, shortened work cycle, shortened downtime, increased tool life, hard materials, tool costs, reduced investment, and others.

7. Cutting parameters of CBN tool

(1) Cutting speed-Vc

The PCD tool can be cut at a very high spindle speed, for example, when turning silicon aluminum alloy, the speed can reach 1000m / min, and high-speed milling 3000m / min;

(2) Feed amount-Fr

According to different processing conditions, the PCD tool should choose the appropriate feed amount. If the feed amount is too large, the surface roughness will be affected, and if it is too small, the cutting temperature will rise;

(3) Cutting depth-ap

PCD tools should choose the appropriate cutting depth according to different processing techniques. Excessive cutting depth will affect the tool life.

8. Common application areas of PCD tools

(1) 3C industry: As consumers demand more and more light, thin, short, small and fashionable, the new technology based on high-tech digitalization, intelligence and networking-"3C" products (Computer, Communication, ConsumerElectronics) endlessly, the number and variety of products is extremely rich. In the case of "3C" products, magnesium aluminum alloy has gradually replaced ABS, PC and other materials. With the development of 5G communication technology, new materials ceramics (zirconia) are more and more used in mobile phone back shells and other fields.

(2) Automotive industry: Aluminum alloy has become an ideal material for the transportation industry to reduce weight. There are many kinds of aluminum alloys in the market, and the Si content of automobile pistons, wheels, engine skirts, pin holes and cylinder blocks More than 10%, at the same time, it adopts the pipeline operation method, so it has high requirements on the hardness and service life of the tool, and the metal matrix composite material (MMC) and carbon fiber composite material have also been applied to the automobile field. Speed and processing quality.

(3) Aerospace industry: The most common composite material used in aerospace is CFRP (carbon fiber W strong plastic). Carbon fiber composite materials currently account for about 50% of the fuselage materials, and PCD tools are particularly effective for it. Typical CFRP parts are the spar of the aircraft, as well as bearings, pump parts and sleeves made of this part material.