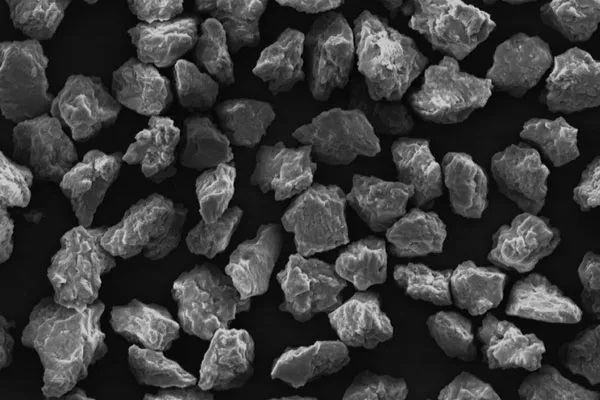

Consistency is a fundamental requirement in the production of micron diamond powder. In industries such as precision polishing, cutting, and surface finishing, even the slightest variation in diamond particle characteristics can affect product performance. A professional micron diamond powder manufacturer must therefore focus on maintaining uniformity in particle size, shape, and surface condition throughout every batch. For polycrystalline diamond powder, which features multiple micro-crystals within each grain, consistency ensures that the abrasive behaves predictably during application. E-Grind's production process emphasizes controlled crystal formation and precise particle classification, resulting in powders that deliver stable and repeatable performance across a wide range of industrial uses.

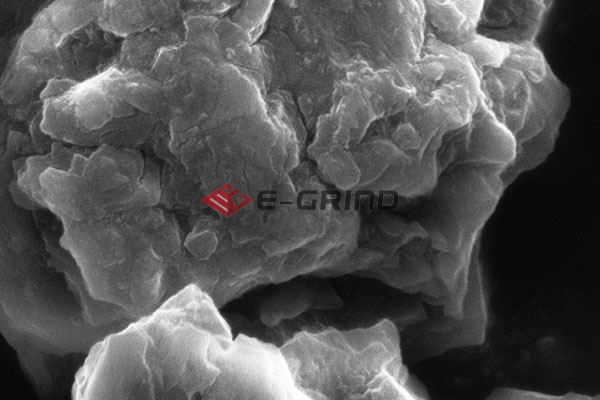

To ensure both consistency and purity, a micron diamond powder manufacturer must rely on advanced synthesis and post-processing methods. Polycrystalline diamond powder is typically created under high temperature and high pressure, forming interconnected micro-grains that provide superior toughness and cutting edges. Once synthesized, the material undergoes rigorous crushing, shaping, and air classification steps to achieve accurate particle size distribution. In E-Grind's process, advanced screening and precision grading technology help eliminate oversized or irregular particles, maintaining a narrow particle size tolerance. The use of automated systems for size measurement and feedback allows continuous quality monitoring, ensuring that every lot of powder meets the strict specifications required by high-precision applications such as semiconductor wafer polishing and ceramic lapping.

Purity is another key parameter that defines the quality of micron diamond powder. Impurities such as metallic inclusions or non-diamond residues can cause surface scratches, reduce polishing efficiency, or even damage high-value substrates. Manufacturers maintain purity through several integrated control stages. During synthesis, the choice of raw materials and catalysts directly impacts purity levels. High-purity graphite sources and optimized reaction environments minimize contamination. After synthesis, acid washing, magnetic separation, and high-temperature purification treatments are applied to remove residual impurities. E-Grind's approach focuses on achieving chemical cleanliness without compromising the crystal integrity of the polycrystalline diamond powder. The result is a highly pure abrasive material suitable for optical components, electronic parts, and superhard coatings where flawless finishes are essential.

A reputable micron diamond powder manufacturer maintains strict quality testing at every stage of production. Particle size and morphology are verified through laser diffraction and electron microscopy, while surface chemistry and purity levels are analyzed using spectroscopic techniques. These tests ensure that each batch aligns with international standards for particle uniformity and cleanliness. Consistency between lots is critical for customers who rely on stable performance in automated production lines. The continuous evaluation of parameters such as flowability, dispersion, and bonding behavior ensures predictable performance when the powder is used in resin, metal, or vitrified bond systems. Through such standardized testing and traceability systems, E-Grind ensures that its micron diamond powders deliver the same high quality from the first kilogram to the last.

The reliability of a micron diamond powder manufacturer is best reflected in the performance of its materials in real-world applications. Consistent and pure polycrystalline diamond powder is widely used in polishing optical glass, sapphire substrates, and hard alloys, where precision surface finishing determines product functionality. It is also employed in producing diamond tools, wire-drawing dies, and advanced coating materials that require stable cutting and abrasion behavior. In semiconductor processing, the uniformity of micron diamond powder contributes to achieving nanometer-level flatness on wafers. Across these applications, the controlled crystal structure and cleanliness of the powder ensure that surfaces are smooth, defect-free, and optically clear. The continued refinement of production and quality systems by leading manufacturers such as E-Grind supports industries that demand the highest levels of precision and reliability.