For over five decades, E-Grind Abrasives has been at the forefront of superabrasive technology, specializing in high-quality diamond dust abrasive that deliver unparalleled performance in precision grinding and finishing applications. Our diamond dust solutions stand as a testament to our commitment to quality, precision, and customer satisfaction.

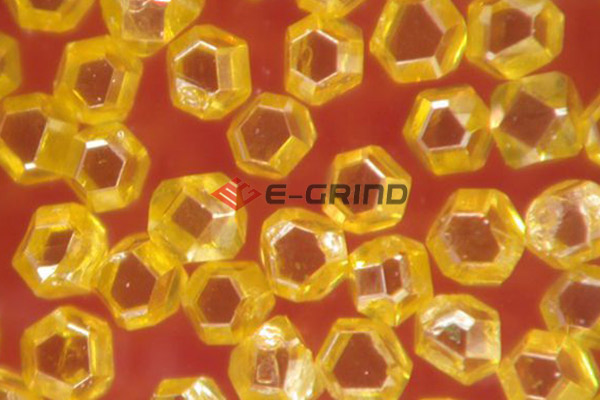

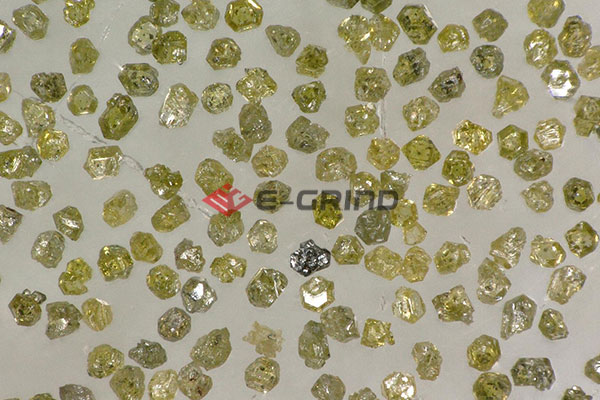

Diamond dust abrasive from E-Grind Abrasives represents the pinnacle of precision finishing technology. With its exceptional hardness ranking 10 on the Mohs scale, our diamond dust abrasive outperforms conventional abrasives in creating mirror-like finishes on the hardest materials, including ceramics, glass, and carbide alloys. The uniform particle size distribution and consistent quality of our diamond dust ensures repeatable results batch after batch, making it the preferred choice for industries demanding micron-level tolerances.

When comparing surface finishing solutions, diamond dust abrasive demonstrates clear advantages over traditional alternatives. While silicon carbide and aluminum oxide abrasives might serve basic grinding needs, diamond dust maintains its cutting edges longer, provides superior heat dissipation, and achieves finer finishes with less material wastage. Our comparative testing shows that diamond dust abrasive can endure three to five times longer than conventional abrasives when working with ultra-hard materials, significantly reducing both processing time and consumable costs for our clients.

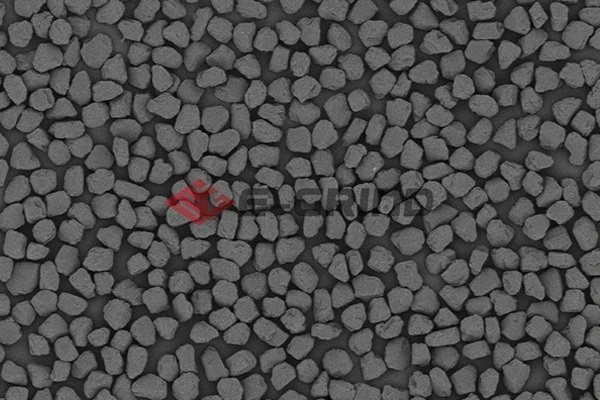

E-Grind Abrasives' diamond dust abrasive plays a critical role in numerous precision manufacturing processes. The semiconductor industry relies on our diamond dust for wafer polishing, while optical manufacturers use it to create distortion-free lenses and mirrors. In the automotive sector, diamond dust enables the precise finishing of fuel injector components, and in the watchmaking industry, it's indispensable for creating perfect bearing surfaces. Our diamond dust abrasive adapts to both lapping and polishing processes, delivering consistent results across various industrial applications.

Choosing the optimal diamond dust abrasive requires careful consideration of particle size, concentration, and bonding method. E-Grind Abrasives offers comprehensive solutions ranging from coarse 40-micron abrasives for rapid stock removal to sub-micron powders for final polishing. Our technical team works closely with clients to match our diamond dust abrasive products to specific material removal requirements, surface finish specifications, and application environments, ensuring maximum efficiency in every operation.

Quality assurance forms the cornerstone of our diamond dust abrasive production. Every batch undergoes rigorous testing for particle size distribution, purity, and abrasive performance before leaving our facility. The traceability of our production process guarantees consistency, while our advanced manufacturing techniques ensure that each micron of our diamond dust abrasive meets the highest industry standards. This commitment to quality has made E-Grind Abrasives the trusted partner for manufacturers worldwide who cannot compromise on precision finishing results.