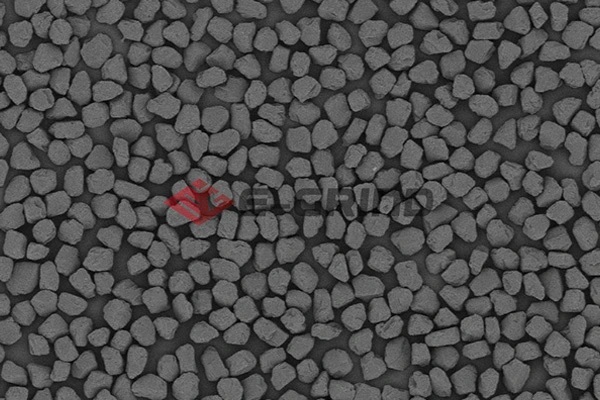

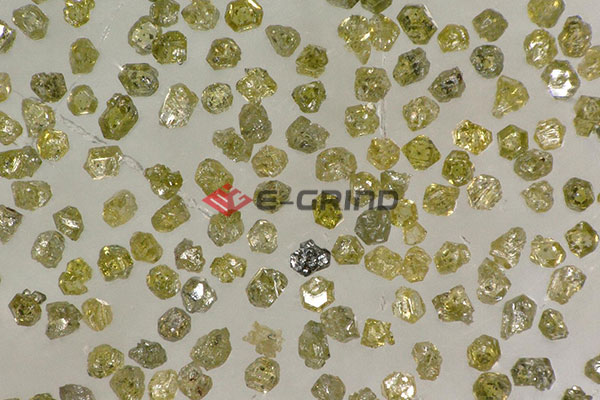

Diamond dust abrasive is an essential material in the polishing of optical components, known for its superior hardness, sharpness, and uniform particle structure. These features make it ideal for applications requiring extremely fine surface finishes. In optical polishing, even microscopic imperfections can distort light transmission and reflection. The high-quality diamond dust abrasive from E-Grind is engineered through advanced synthesis and grading methods to provide exceptional consistency and purity. Each particle maintains a uniform shape and controlled size distribution, allowing smooth, predictable abrasion that produces flawless optical surfaces. Its stable crystal structure ensures uniform material removal without introducing subsurface damage, making it one of the most reliable abrasives for precision polishing processes.

Optical components such as lenses, prisms, and mirrors require perfectly smooth surfaces to maintain precise optical paths. Diamond dust abrasive plays a crucial role in this process by refining rough-ground optical surfaces into ultra-smooth finishes with minimal scattering. The hardness of diamond enables it to remove extremely small surface irregularities without deforming the underlying substrate. When used in conjunction with suitable polishing pads and fluids, E-Grind's diamond dust abrasive achieves high-quality finishes characterized by excellent flatness and clarity. The uniform particle behavior ensures that each contact between abrasive and material contributes evenly to the polishing effect, preventing the formation of scratches or local defects that could impair optical performance.

Diamond dust abrasive enhances optical quality by providing consistent material removal and controlled polishing pressure. In optical manufacturing, achieving high surface uniformity is critical for maintaining precise refractive and reflective properties. The abrasive's extreme hardness ensures that the polishing process remains stable over long durations without particle degradation. This stability prevents uneven wear, which could otherwise lead to variations in optical thickness. Additionally, diamond dust abrasive helps achieve low surface roughness values, improving light transmission through lenses and reducing reflection losses on mirror coatings. In laser optics and imaging systems, this translates directly into sharper focus, reduced optical distortion, and better overall system performance.

Diamond dust abrasive is applied in multiple stages of optical component fabrication. It is commonly used for the final finishing of glass, quartz, sapphire, and infrared crystal substrates. These materials are too hard for conventional abrasives, making diamond dust the only effective option for achieving defect-free surfaces. E-Grind's diamond dust abrasive is also used for polishing high-precision molds and metal optics where surface accuracy directly affects replication quality. In fiber optic connectors, diamond dust ensures ultra-smooth end faces, allowing efficient light transmission and minimal signal loss. Furthermore, in high-power laser systems, its use in mirror and lens finishing ensures stable surface geometry, maintaining consistent beam alignment and preventing energy loss. Across all these applications, diamond dust abrasive provides an unmatched balance between cutting efficiency and surface integrity, which is vital for producing optical components that meet the most demanding specifications.

The effectiveness of diamond dust abrasive in optical polishing depends greatly on material consistency and process control. Variations in particle shape or size can lead to uneven abrasion, affecting optical accuracy. E-Grind's diamond dust abrasive is produced under strict quality standards to guarantee precise particle distribution and purity. During the polishing process, controlling parameters such as pressure, slurry concentration, and movement speed is equally important to maintain uniform polishing action. When these factors are properly balanced, the diamond dust abrasive produces surfaces that are not only optically flawless but also physically stable under different environmental conditions. The consistent use of high-quality diamond dust abrasive ensures reliable polishing performance across multiple batches, enabling manufacturers to maintain the precision and reproducibility demanded by the optical industry.