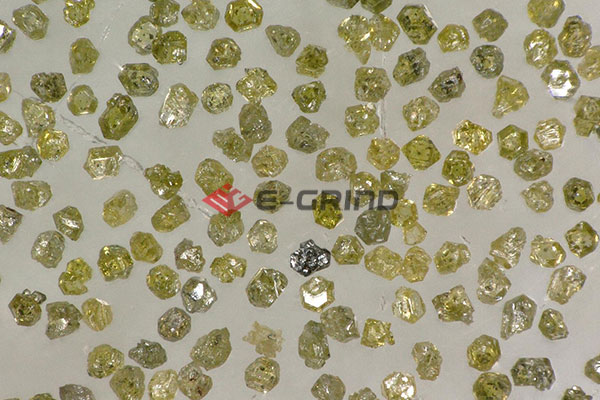

For over 50 years, E-Grind Abrasives has specialized in manufacturing high-quality diamond and CBN abrasives, including premium-grade diamond dust abrasive for precision grinding and polishing. Our commitment to quality control, advanced manufacturing, and full traceability ensures consistent performance for industries that demand flawless surface finishes.

With a full range of grit products for sawing, grinding, lapping, and polishing, we help manufacturers achieve exceptional precision and efficiency in material processing.

Diamond dust abrasive is the go-to solution for industries requiring sub-micron surface finishes. Thanks to its unmatched hardness (10 on the Mohs scale) and fine particle control, it delivers ultra-smooth polishing results for:

Optical lenses & mirrors: Eliminates surface defects for distortion-free clarity.

Semiconductor wafers: Ensures nanoscale uniformity for high-performance microchips.

Medical implants & tooling: Maintains biocompatible and ultra-precise finishes.

E-Grind Abrasives' Diamond Dust is produced under strict quality checks, securing uniform particle distribution for consistent polishing performance.

Feature | Diamond Dust Abrasive | Silicon Carbide |

Hardness | 10 (Highest on Mohs scale) | 9-9.5 (Very Hard but Below Diamond) |

Cutting Efficiency | 5-10x longer lifespan | Wears faster, requiring frequent replacement |

Surface Finish | Achieves mirror-like polish | Limited to rough & semi-finishing |

Best For | Ultra-precision, hardened materials | General abrasive applications |

Diamond dust abrasive outperforms traditional abrasives in longevity, precision, and surface quality, making it the choice for elite manufacturers.

When processing tungsten carbide, ceramics, sapphire, and hardened steels, diamond dust abrasive is unmatched due to:

Superior wear resistance: Maintains sharp cutting edges longer than any other abrasive.

Reduced heat generation: Minimizes material warping during extended grinding.

Super-fine polishing capability: Delivers Ra < 0.01µm finishes that conventional abrasives can't match.

Industrial leaders in aerospace, toolmaking, and electronics rely on E-Grind Abrasives' Diamond Dust for uncompromised precision in super-hard material applications.

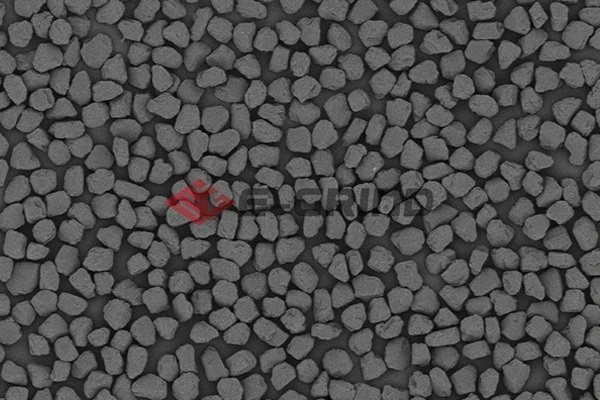

Choosing the correct Diamond Dust particle size directly impacts material removal rate and final surface finish. Consider:

Coarse (40-60µm): Best for fast stock removal and rough grinding.

Medium (15-30µm): Ideal for semi-finishing before final polish.

Fine (0.5-10µm): Used for ultra-precision lapping and mirror polishing.

E-Grind Abrasives provides customized solutions to match your specific grit requirements, ensuring optimal performance for any application.

With half a century of expertise, E-Grind Abrasives remains a leader in superabrasive solutions for precision industries. Our fully traceable manufacturing process and rigorous quality tests guarantee that every batch of diamond dust abrasive meets the highest standards.