For over 50 years, E-Grind Abrasives has been a trusted leader in high-performance polycrystalline diamond powder, delivering precision abrasive solutions for industries that demand exceptional wear resistance, self-sharpening properties, and consistent finishing quality. Our advanced manufacturing expertise ensures that every batch of polycrystalline diamond powder meets the highest industry standards, helping manufacturers achieve higher productivity, longer tool life, and superior surface finishes.

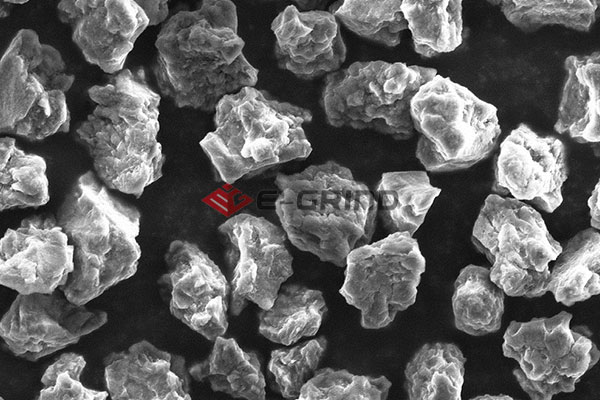

Unlike conventional abrasives, polycrystalline diamond powder (PCD) from E-Grind Abrasives offers unique benefits that enhance grinding, lapping, and polishing processes:

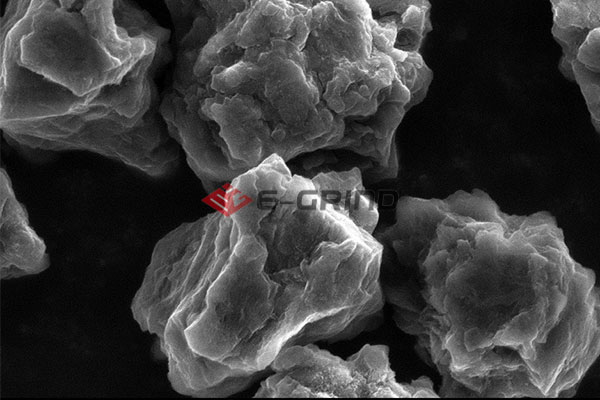

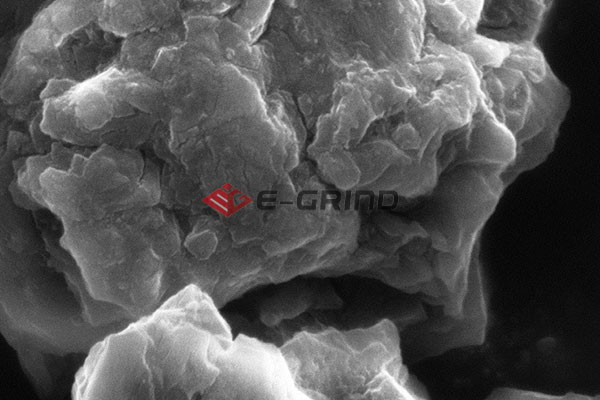

Micro-Fracture Mechanism: The sintered multi-crystalline structure self-sharpens during abrasion, continuously exposing fresh cutting edges for consistent material removal rates.

Exceptional Toughness: More resistant to breakage than monocrystalline diamond, making it ideal for hard and brittle materials like tungsten carbide and advanced ceramics.

Uniform Surface Finish: Produces low roughness values with minimal subsurface damage—critical for optics, semiconductors, and medical implants.

Longer Lifespan: Compared to single-crystal diamond, PCD powder maintains efficiency longer, reducing operational downtime.

By leveraging these properties, E-Grind Abrasives' polycrystalline diamond powder ensures higher precision, cost savings, and process reliability in demanding applications.

Choosing between monocrystalline and polycrystalline diamond powder depends on application requirements. Below is a detailed performance comparison:

Property | Polycrystalline Diamond Powder (PCD) | Monocrystalline Diamond Powder |

Structure | Multiple nano-crystals bonded together | Single-crystal structure with cleavage planes |

Wear Resistance | Higher (due to micro-fracturing) | Lower (prone to cleavage) |

Cutting Edge Retention | Self-sharpening for consistent performance | Degrades faster |

Best Applications | Hard & brittle materials, long-duration lapping | High initial sharpness, fine polishing |

E-Grind Abrasives recommends polycrystalline diamond powder for hard material grinding and extended processing cycles where durability matters most.

E-Grind Abrasives' polycrystalline diamond powder is engineered for precision applications across critical industries:

Aerospace & Defense: Machining ceramic composites, turbine blades, and high-strength alloys with minimal micro-cracking.

Optics & Electronics: Producing ultra-smooth surfaces for lenses, silicon wafers, and laser components.

Medical Devices: Finishing surgical tools and implants to sub-micron roughness levels.

Automotive: Lapping carbide cutting tools and engine components for extended service life.

These solutions highlight PCD powder's versatility, making it indispensable for high-value manufacturing sectors.

As a pioneer in superabrasive technology, E-Grind Abrasives ensures long-term value for customers through:

Advanced Quality Control: Rigorous testing for particle size distribution, purity, and bulk density consistency.

Customizable Solutions: Tailored grit sizes (0.1–50µm) for optimized MRR and surface finishes.

Traceable Manufacturing: Full documentation ensures supply chain transparency and reliability.

By choosing E-Grind Abrasives, industries gain a trusted partner committed to performance-driven polycrystalline diamond powder solutions.