For over 50 years, E-Grind Abrasives has been a leading manufacturer of premium diamond dust abrasive, delivering high-performance diamond powder for precision grinding, lapping, and polishing applications. One of the most critical yet often overlooked properties of diamond dust abrasive is bulk density—a key factor that directly impacts material suspension, abrasion efficiency, and polishing consistency. Understanding this property helps manufacturers optimize grinding performance, tool life, and surface finish quality.

Bulk density refers to the mass of diamond powder abrasive particles per unit volume when loosely packed. Unlike single-crystal density (which measures pure diamond hardness), bulk density determines how diamond powder flows, settles, and mixes in different applications such as:

Diamond slurry preparation for precision polishing.

Resin-bonded or metal-bonded grinding wheels.

Electroplated diamond tools.

A higher bulk density means more diamond concentration per volume, while a lower density may indicate more air gaps between irregularly shaped particles. E-Grind Abrasives' diamond powder undergoes strict particle size distribution control, ensuring optimal bulk density for uniform performance.

The bulk density of diamond dust abrasive varies significantly based on two main factors:

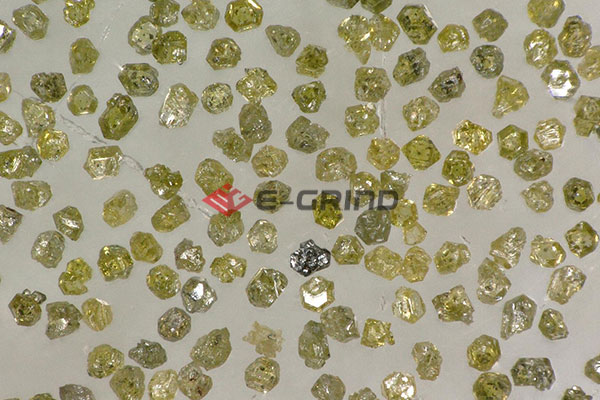

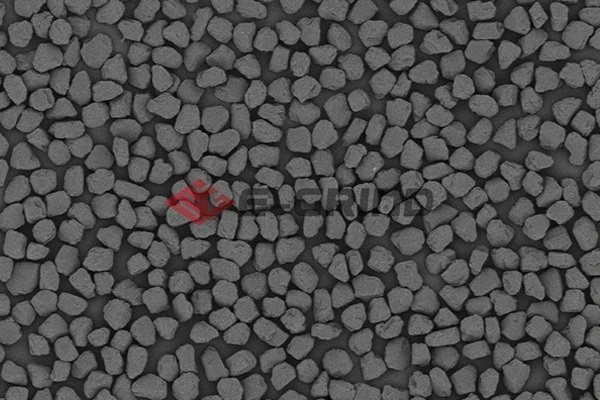

Particle Shape

Blocky, irregular crystals have lower bulk density due to inefficient packing.

Uniform, spherical synthetic diamond particles (like high-quality monocrystalline diamond) fill space more efficiently, yielding higher bulk density.

Particle Size Distribution

Narrowly graded diamond powder (single micron range) tends to settle more densely.

Broadly distributed micron powder (multi-size mix) may have lower bulk density due to voids between different-sized particles.

E-Grind Abrasives optimizes bulk density by carefully controlling crystal structure, particle shapes, and grading processes, ensuring consistent performance in grinding, lapping, and polishing applications.

While diamond dust abrasive remains the hardest and most efficient abrasive, its bulk density characteristics differ from other superabrasives and conventional abrasives.

Property | Diamond Dust Abrasive | Silicon Carbide (SiC) | Cubic Boron Nitride (CBN) |

Bulk Density (g/cm³) | 1.5–2.0 (varies by grade) | 1.6–2.2 | 1.7–2.1 |

Particle Shape Influence | More density variation due to natural/synthetic shapes | More uniform grains | More controlled shape |

Effect on Polishing Slurries | Suspends differently based on density | Settles faster | Intermediate suspension |

The high bulk density of diamond powder abrasives ensures better cutting consistency, but manufacturers must consider how settling behavior impacts slurry stability and tool loading.

Does Bulk Density Influence Lapping and Polishing Performance?

Yes—bulk density directly impacts material removal rate (MRR) and surface finishing quality in diamond dust abrasive applications:

High-Density Diamond Powder

More abrasive particles per volume → faster stock removal.

Requires less replenishment in slurry systems.

Preferred for aggressive lapping and grinding.

Low-Density Diamond Powder

Better suspension in polishing fluids (less settling).

Ideal for ultra-precision finishing where fine control is needed.

E-Grind Abrasives' diamond powders are engineered with consistent bulk densities, ensuring repeatable results across grinding, lapping, and polishing processes.

To select the optimal diamond dust abrasive for your process, consider these guidelines:

For High MRR (Grinding/Lapping): Choose higher bulk density grades (rougher grits, uniform particles).

For Ultra-Smooth Finishing (Polishing): Lower-density, well-suspended micron powders.

For Slurry-Based Applications: Test suspension stability—finer powders with controlled density prevent sedimentation.

E-Grind Abrasives provides specialized guidance to help manufacturers select the ideal diamond powder abrasive for their precision finishing needs.

With decades of experience in diamond abrasives, E-Grind Abrasives stands as a trusted global supplier of premium diamond powder products. Our commitment to precision manufacturing and strict quality control ensures that every batch delivers:

Optimized bulk density for superior process control.

Consistent particle size distribution.

Full traceability from raw diamond to finished product.