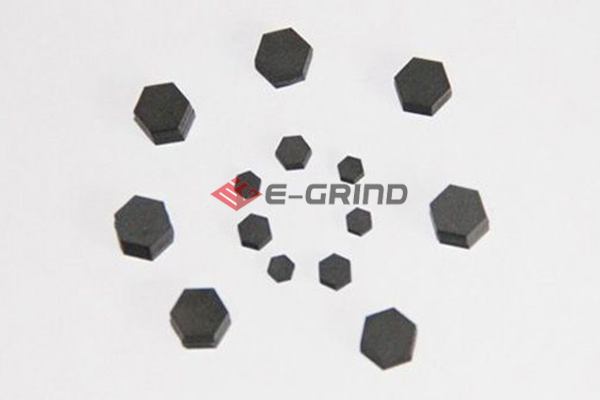

PCD die blanks, or polycrystalline diamond die blanks, are the foundation of high-performance wire drawing dies used across industries such as electrical, automotive, and telecommunications. These materials combine diamond's unmatched hardness with engineered toughness, allowing for superior wear resistance and long service life. E-Grind's diamond wire drawing die blanks represent a class of high-precision materials produced under carefully controlled conditions, ensuring uniform grain distribution and consistent cutting performance. The surface quality of PCD die blanks is a critical factor influencing the accuracy, smoothness, and durability of the final wire drawing dies.

Laser processing has become an advanced method for machining PCD die blanks due to its high precision, non-contact nature, and capability to handle ultra-hard materials. Traditional mechanical grinding often faces challenges like micro-cracking and tool wear, while laser machining minimizes these issues by using concentrated energy to ablate material without significant mechanical stress. When applied to E-Grind's PCD die blanks, laser technology ensures precise control over the cutting process, achieving cleaner edges and smoother surfaces that enhance the performance of wire drawing dies.

The surface finish of PCD die blanks during laser processing is influenced by several interrelated parameters, including laser power, pulse duration, frequency, and scanning speed. Higher laser power increases the material removal rate but can also lead to microstructural damage if not controlled properly. On the other hand, shorter pulse durations reduce thermal effects, resulting in finer surface textures and fewer microcracks. Adjusting the laser frequency and scanning speed allows for optimized energy distribution, leading to uniform ablation and improved surface integrity. For PCD die blanks supplied by E-Grind, precision in parameter control ensures that the resulting surfaces are smooth, defect-free, and ideal for producing high-quality drawing dies.

The correlation between laser parameters and surface quality directly affects the performance of PCD die blanks in application. A properly optimized laser setup can reduce roughness, minimize subsurface damage, and improve the adhesion characteristics for subsequent polishing or coating processes. As a result, wire drawing dies made from these blanks exhibit longer operational lifespans and maintain dimensional accuracy even under continuous high-load operation. E-Grind's PCD die blanks, when processed with optimized laser conditions, demonstrate excellent surface uniformity, which contributes to consistent wire flow and reduced friction during production.

With continuous advances in laser machining technology, future developments will further enhance the surface precision of PCD die blanks. The integration of ultrafast laser systems, real-time feedback control, and automated parameter optimization will make it possible to achieve nanometer-level surface smoothness. E-Grind is actively supporting these innovations by supplying PCD die blanks engineered for compatibility with cutting-edge processing technologies. These improvements will not only refine surface quality but also expand the functional possibilities of PCD die blanks in various high-demand manufacturing sectors.