For over fifty years, E-Grind Abrasives has been at the forefront of superabrasive manufacturing, specializing in high-performance polycrystalline micron diamond (PCD) powder for precision grinding and polishing applications. As a trusted leader in diamond abrasives, we provide cutting-edge solutions engineered for ultra-hard materials, delivering unmatched consistency, durability, and surface refinement for critical industrial applications.

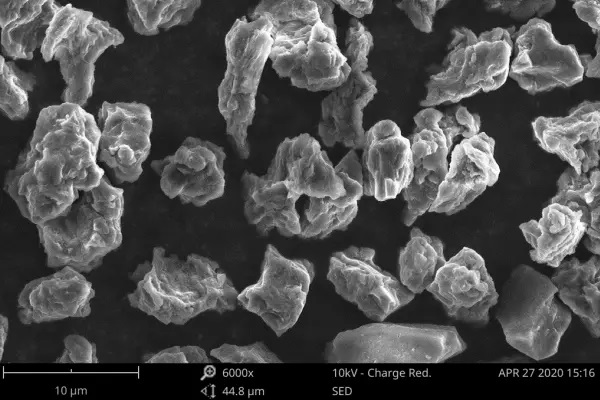

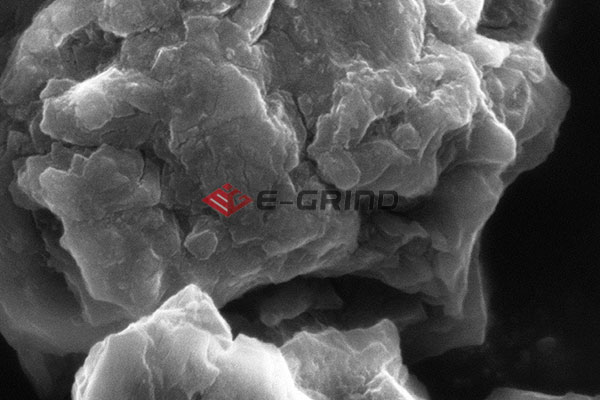

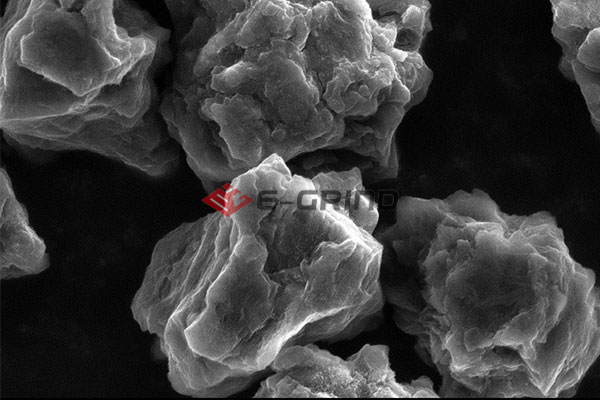

Unlike traditional monocrystalline diamond, polycrystalline micron diamond (PCD) is composed of countless microscopic diamond crystals sintered together under high pressure, creating an abrasive with exceptional toughness and self-sharpening properties. This unique structure allows PCD to maintain consistent cutting efficiency over time, reducing tool wear and improving surface finish quality.

E-Grind Abrasives' PCD powders are specially optimized for:

Lapping & polishing of tungsten carbide, ceramics, and composite materials.

Precision grinding of aerospace components.

Optical lens finishing with minimal sub-surface damage.

This makes polycrystalline micron diamond indispensable for industries that demand long-lasting abrasive performance.

When selecting diamond abrasives, understanding the difference between polycrystalline and monocrystalline diamond powder is crucial for performance and cost-efficiency:

Fracture Behavior: Monocrystalline diamonds cleave along crystal planes, leading to rapid edge degradation, while polycrystalline micron diamond undergoes micro-fracturing, continuously exposing fresh cutting edges.

Surface Finish: Monocrystalline diamond provides sharper initial cuts, but PCD delivers more uniform finishing due to its self-renewing abrasive action.

Material Compatibility: PCD outperforms monocrystalline diamond in brittle and composite materials, reducing chipping and improving edge retention.

Performance Comparison Table

Property | Polycrystalline Micron Diamond | Monocrystalline Diamond |

Wear Resistance | Exceptionally high | Degrades faster due to cleavage |

Cutting Consistency | Self-sharpening over time | Performance drops with wear |

Optimal Use Case | Long-duration polishing & lapping | Quick stock removal & sharp initial cuts |

E-Grind Abrasives' PCD powder ensures stable performance, making it ideal for high-volume finishing operations.

In industries such as aerospace, optics, and semiconductor production, PCD abrasives play a vital role in achieving micron-level tolerances and defect-free surfaces. Key applications include:

Ultra-Precision Lapping of Optical Components: Ensures minimal subsurface damage for lenses and mirrors.

Advanced Ceramic Machining: Provides controlled material removal without micro-cracking.

Carbide Tool Refinement: Enhances tool longevity with ultra-smooth edge finishes.

With superior fracture toughness and multi-directional cutting ability, polycrystalline micron diamond is the preferred choice for manufacturers requiring high repeatability and extended abrasive life.

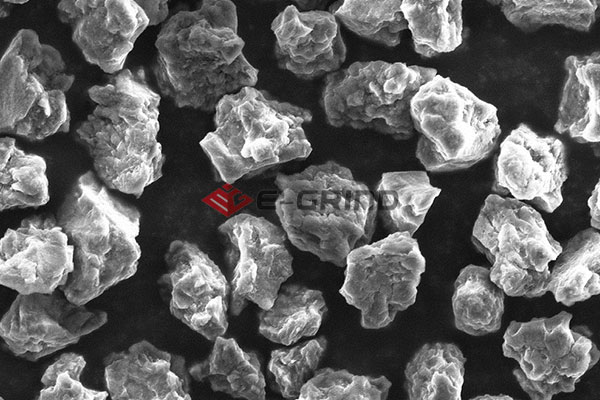

Choosing the ideal PCD grit size depends on the desired material removal rate (MRR) and final surface roughness:

Coarse (10-40µm): Best for aggressive stock removal in rough grinding.

Medium (2-10µm): Ideal for semi-finishing before final polish.

Fine (<2µm): Used for achieving ultra-smooth, nano-finish surfaces.

E-Grind Abrasives offers a full spectrum of grit sizes, enabling manufacturers to optimize their grinding and polishing processes for maximum efficiency.

With 50+ years of abrasive expertise, E-Grind Abrasives combines advanced manufacturing techniques with rigorous quality control to produce PCD powder of the highest consistency and performance. Every batch undergoes strict inspection to ensure:

Uniform particle size distribution for predictable abrasion performance.

High purity and controlled crystal structure for consistent results.

Full traceability from raw material to finished product.

Manufacturers across the globe rely on E-Grind Abrasives' polycrystalline micron diamond for unmatched durability and precision finishing.