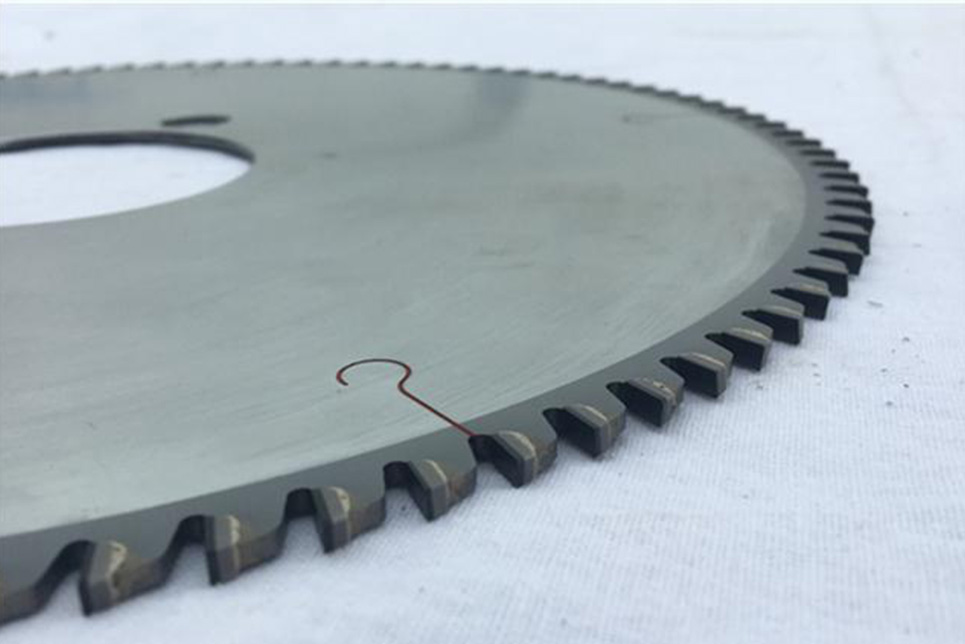

Diamond saw blade, a multi-blade tool with outstanding sawing performance. At the beginning of its birth in 1885, it was made by a Frenchman by welding natural diamonds on the matrix.

Today, with the birth and maturity of saw powder metallurgy technology, the cost of diamond saw blade manufacturing and the performance of the saw blade itself are also increasing. In addition to being used for sawing aluminum and wood, the processing of some brittle and hard materials is inseparable from the diamond saw blade.

Let's take the common brittle and hard material stone as an example. Due to the rigidity and wear resistance of the saw blade itself has very high requirements, in the sawing process of such materials, only diamond saw blades can be competent.

From the current application scenario, aluminum, wood, granite, concrete, steel, ceramics, glass, wood, plastic, etc., are the main battlefield of diamond saw blade application.

It can be said that diamond saw blade is completely worthy of the high performance. At present, in the entire process of manufacturing diamond saw blades, in addition to the matrix and sawtooth, the quality of welding is also a key factor in determining the performance of diamond saw blades.

From the analysis of the force in the working process of the diamond saw blade, you will understand the importance of the quality of the welding teeth for a diamond saw blade.

When the diamond saw blade in high-speed rotation contacts the profile, the edge of the sawtooth will bear a series of relative forces such as cutting stress and thermal stress in an instant.

As a bridge between the diamond saw blade matrix and the sawtooth, the quality of the weld or welding technology actually determines the final sawing performance of a diamond saw blade.

At present, the most commonly used sawtooth welding technology in the production and manufacture of diamond saw blades is high-frequency brazing.

Through automatic high-frequency tooth welding, one cutter head after another is welded on the tooth holder. During the entire welding process, the debugging of the welding equipment and the performance of the solder determine the final performance of a diamond saw blade to a certain extent.

In terms of the cost of diamond saw blade manufacturing alone, high-frequency brazing is still a compromise between cost and performance. It is also the most widely used welding method at present.