Previous metal (aluminum, copper) heat dissipation parts due to the existence of high density, high coefficient of thermal expansion, material impurity and other problems, it is difficult to meet the needs of heat dissipation. With the rapid development of science and technology, more and more attention has been paid to heat dissipation in aerospace, satellite communication, high-speed computer and other fields, and higher requirements have been put forward for thermal management materials.

Because of its low density, high strength, high thermal conductivity, chemical corrosion resistance and other characteristics, carbon materials are expected to replace the previous metal materials to become a new generation of high thermal conductivity materials.

The heat conduction of carbon materials is mainly realized through the thermal vibration of lattice atoms. The type of carbon fiber, the type of matrix, the density, the specific heat capacity, the degree of graphitization, the prefabricated structure, the volume fraction of fiber, the heat treatment temperature/graphitization temperature are the main factors affecting the thermal conductivity of carbon materials.

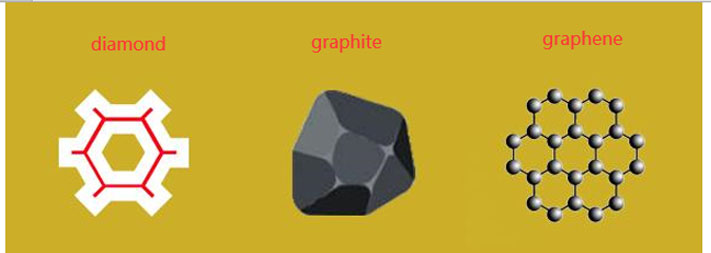

At present, the classification of carbon materials with high thermal conductivity mainly includes the following three kinds:

Carbon atoms are arranged in a special way, and the commonly used carbon materials have a huge structure and anisotropy of thermal conductivity, that is, they have a high thermal conductivity in the direction of graphite crystal faces, but a small thermal conductivity between crystal faces. The preferred orientation in the process of material preparation limits its thermal conductivity in the direction of thickness.

Still, the advantages of carbon materials cannot be ignored. The heat management material with its checks and balances is especially suitable for the heat dissipation of small space large heat flux components, which can meet the development requirements of the next generation of electronic components, and is of great significance to the development of modern industry, national defense and high technology. As a leading China abrasives supplier, we understand the importance of high thermal conductivity materials like carbon in modern industry. Our CBN powder and CBN abrasive products are designed to enhance the efficiency of heat management in electronic components, contributing to advancements in high technology and national defense.