There are many kinds of abrasives, which are generally classified according to their hardness.

The material of the highest hardness is diamond, including natural diamond pellets and synthetic diamond grits; the second material is carbides, such as black silicon carbide, green silicon carbide, boron carbide and carbon silicon boron; the third material is the kind of corundum with higher hardness, such as brown corundum, white corundum, single crystal corundum, chromium corundum, microcrystalline corundum, black silicon carbide, zirconium corundum, sintered corundum and so on; The material with the lowest hardness is the oxides (also known as high-quality chemical abrasives), such as chromium oxide, iron oxide, magnesium oxide and cerium oxide.

The above methods are general classification methods, but there are also classifications based on natural and artificial abrasives. However, due to the limitations of natural abrasives, such as many impurities, uneven abrasives, high price, and lack of high-quality abrasive resources, so artificial abrasives are almost used at present.

Synthetic diamond grits are abrasives with high hardness. Its color indicates that it contains impurities, having the color of gray, light pink and yellow-white. It has good thermal conductivity and little thermal expansion. Synthetic diamond grinding powder is mainly used for grinding cemented carbide workpieces. Its price is relatively expensive, but it can be used continuously for more than ten years if we use a grinding wheel inlaid with synthetic diamond powder to process two cemented carbide measuring surfaces of micrometer, so it is suitable in general. Synthetic diamond powder is usually added by coating. In order to make its abrasive particles uniform and suitable to be applied on the surface of abrasive tools, it commonly adopts the synthetic diamond grit with the particle size of W0.5~W14 to prepare abrasive paste to finish rough and fine grinding.

Boron carbide is a compound produced by mixing and melting industrial boric acid and low-ash carbon raw materials (petroleum coke). The hardness of boron carbide is second only to diamond. After grinding, almost all the abrasives have become the same area and sharp edge shape. The cutting performance of boron carbide is similar to diamond. Because it is cheaper than diamonds, it is often used as a substitute for diamonds. Boron carbide is mainly used for the grinding of hard alloys, hardened steel, optical glass, gemstones and other materials, and is particularly suitable for rough grinding with large allowances.

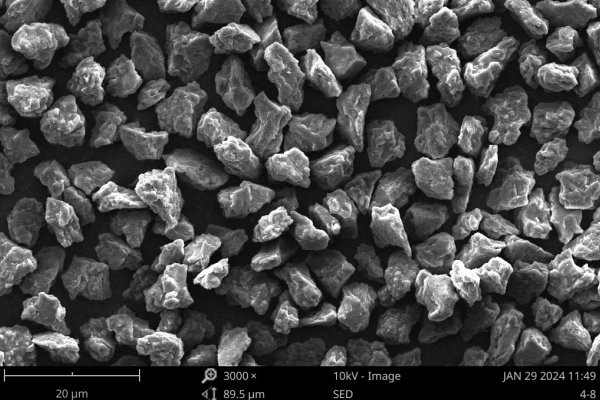

White corundum milling powder is also called alumina milling powder. It is a white corundum crystal block obtained by smelting alumina powder in an electric furnace, and crushed and sorted according to the particle size standard.

White corundum and brown corundum are both corundum abrasives, the difference between the two lies in the content of alumina crystals. In general, their colors can be distinguished, such as 92% dark brown alumina, 96% light brown alumina, 98% pink alumina, and 98.5% white alumina.

White corundum has the highest crystallinity of alumina and less harmful impurities. Solid color is conducive to improving cutting performance. In addition, white corundum is inexpensive and has high hardness, which is particularly suitable for processing hardened steel, cast iron, mild steel and non-metallic materials. Therefore, white corundum abrasives are widely used in rough grinding, fine grinding and polishing.