The diamond powder uses are wide. Industrial diamond powder has the characteristics of high thermal stability, high chemical stability, good conductivity, good physical properties (high compressive strength, good heat dissipation, strong corrosion resistance, low thermal expansion rate) and so on. It has high hardness and good wear resistance, and can be widely used for cutting, grinding and drilling. Diamond abrasive powder has high thermal conductivity and good electrical insulation, which can be used as a heat sink for semiconductor devices. Besides, diamond powder abrasive has excellent light transmission and corrosion resistance, and is widely used in the electronics industry.

Approximately 90% of diamonds used in various industries are manufactured synthetically. E-Grind, as a professional synthetic diamond powder manufacturer and supplier, has high-quality diamond powder for sale. We have advanced production and testing equipment with more than 40 years of production experience, which enables us to stand out among all the diamond dust suppliers. We professional provide our customers with high-quality synthetic diamond abrasives and competitive prices for various types of synthetic diamond abrasives. You can click and check more informations about our different types of diamond grinding powder. If you are looking for trustworthy diamond dust suppliers, don't hesitate to contact us. E-Grind is your reliable synthetic diamond powder supplier and manufacturer.

Processing Glass, PCD/PCBN, Dental tools and Stone polishing tools, please choose our Metal bond mesh product made with high-quality synthetic diamond dust.

Machining nonferrous materials like tungsten carbide, glass and different kinds of ceramics, please use our Resin bond Diamond, EA-R series, which utilizes premium diamond dust abrasive for superior cutting and grinding performance.

To make Diamond Grinding wheels with Metal bond and Electroplated, please choose our Wheel Grit, ED-F series. To make Diamond grinding wheels with Resin bond, please use our Resin bond diamond, EA-R series. For Vitrified bond, please use our Metal bond mesh series.

Stone processing, construction industry, for sawing, grinding and drilling of stone, asphalt and concrete, please choose our Saw grit, EA-M series products, which ensure long-lasting performance with consistent synthetic diamond powders.

Lapping, Polishing and Finishing Gem, Electronic parts, Stone. Please choose our EA-RW and EA-MW micropowder series products.

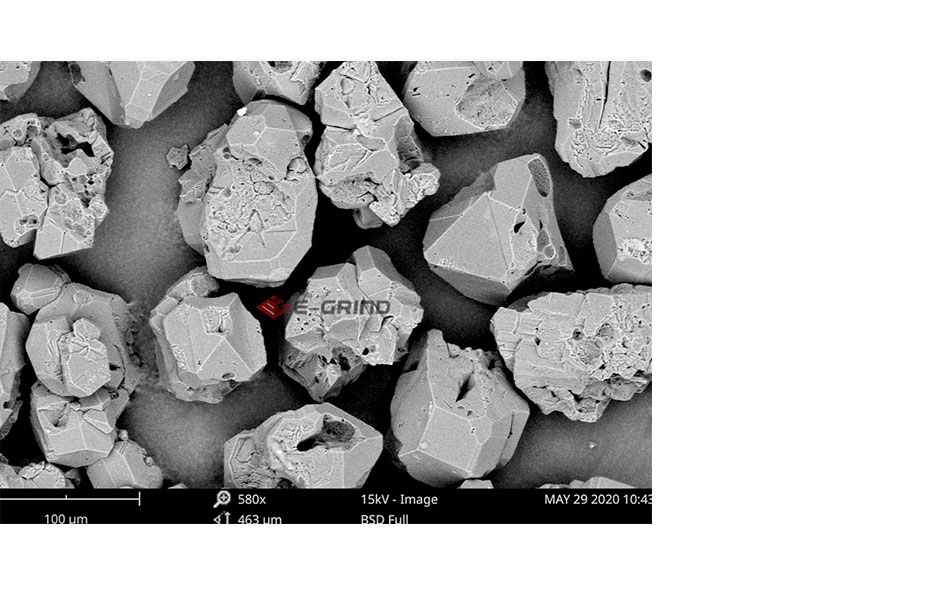

High thermal and chemical stability of industrial diamond powder

High compressive strength, good heat dissipation, strong corrosion resistance, low thermal expansion rate.

High hardness and good wear resistance

High thermal conductivity and good electrical insulation

Excellent light transmission

With over 50 years of experience, E-Grind is a global leader in superabrasives and one of the reliable diamond powder manufacturers:

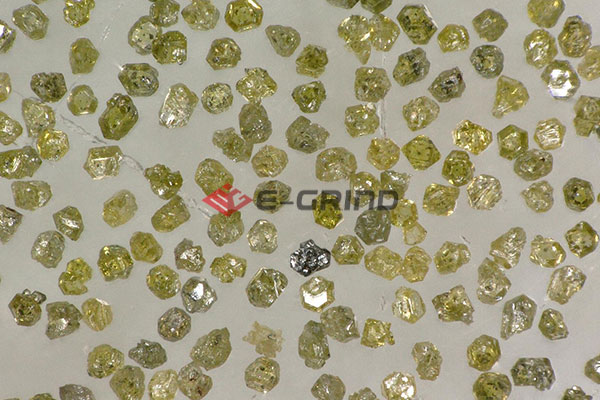

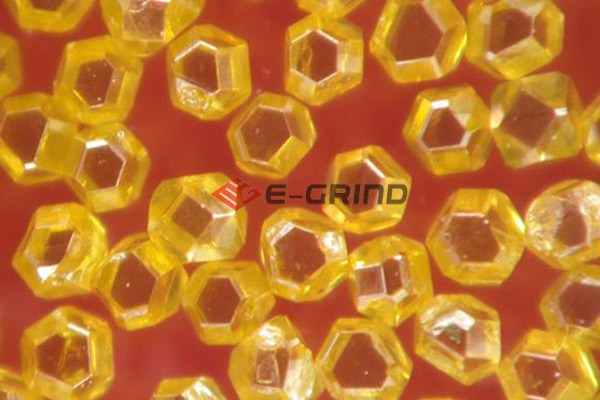

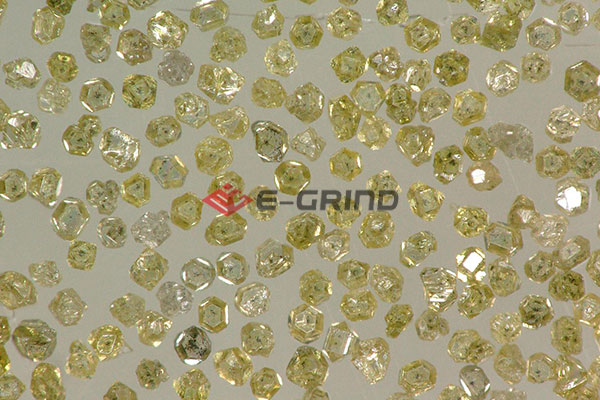

Advanced Manufacturing: Utilizes HPHT and CVD processes for consistent quality.

Rigorous Quality Control: Every batch is tested for particle size, purity, and performance.

Custom Solutions: Tailored coatings (nickel, titanium, copper) and particle sizes to meet your needs at competitive abrasive diamond powder price.

Trusted by Industry: Proven results in toolmaking, electronics, and more using reliable diamond grinding powder.

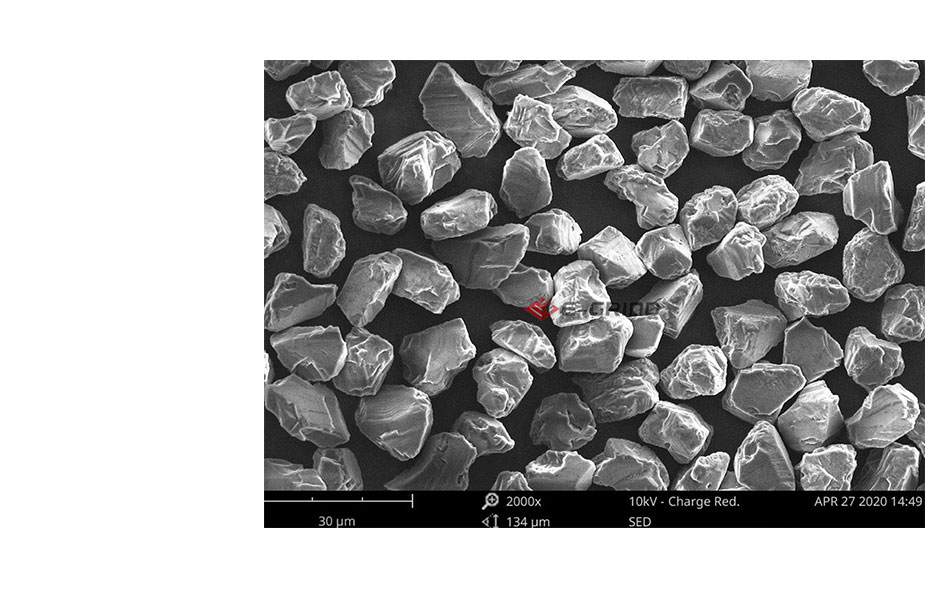

Synthetic diamond powder is finely ground diamond particles (0–50 microns) produced in labs using HPHT or CVD methods, used for cutting, grinding, and polishing due to their extreme hardness and thermal stability.

They offer superior hardness, thermal conductivity, precision finishes, cost-effectiveness, and ethical sourcing compared to natural diamonds.

E-Grind provides particle sizes from 0–50 microns, including nano-diamond powders for high-precision applications.

It's used in grinding wheels, polishing pads, and cutting tools to achieve smooth, precise finishes on hard materials like ceramics and semiconductors.

Its unmatched hardness and self-sharpening properties ensure faster material removal, smoother surfaces, and longer tool life.

While non-toxic, fine diamond dust can irritate the respiratory system or skin if mishandled. Use proper PPE and ventilation.