E-Grind produces high-quality Polycrystalline diamond composite(PDC) and polycrystalline diamond compact cutters.

E-Grind can provide a full range of diamond PDC with diameters ranging from 8mm to 19mm. We can also provide polycrystalline diamond compact cutters which can be customized according to customer needs, including special-shaped polycrystalline diamond cutters for different drilling environments.

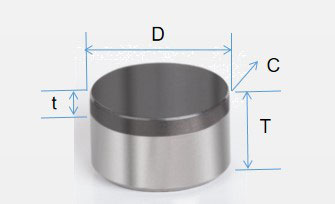

D+T is generally used to indicate product specifications

C is Diamond chamfer, the standard degree is 45°, 0.3 mm length.

Diamond table (t) thickness is 2.0 mm, 1.5 mm, 1.0mm.

Dimension can be customized according to customer needs

Available Spec for Oil/gas Grade

| D\T | 16 | 13 | 10 | 8 | 4 |

| 19 | * | • | * | * | o |

| 16 | * | • | * | • | o |

| 13 | o | • | * | • | • |

| 10 | o | o | • | • | • |

| 8 | o | o | o | • | • |

Available Spec for Mining Grade

| D\T | 16 | 13 | 10 | 8 | 4 |

| 19 | o | • | * | • | o |

| 16 | o | • | * | • | o |

| 13 | o | * | * | • | • |

| 10 | o | o | • | • | • |

| 8 | o | o | o | • | • |

| Note | |

| • | Available |

| o | NA |

| * | Customize |

|

Diamond Table The uniform micron size distribution, make PDC high bonding force and high density.Various particle sizes can meet customer needs for wear resistance and impact resistance demand. |

|

Interface We have various interface designs to ensure optimal combination between the diamond table and the substrate, improving the reliability of each polycrystalline diamond compact bit. |

|

Substrate E-Grind using 13% and 16% Co carbide substrate as standard specificaiton. Ensure the carbide substrate brazed strength to the drill bit body. |

Diamond-reinforced composite cutter are formed by sintering diamond particles and cemented carbide matrix at high temperature and pressure, which not only has the high wear resistance of diamond, but also has the high strength of cemented carbide. The products are widely used in roller cone bits, down-the-hole drill bits, picks, crushing machinery and other fields, and are the best substitute for cemented carbide cutter.

The diamond-reinforced composite cutter adopts the transition layer technology between the diamond layer and the cemented carbide layer, which has outstanding impact resistance and ultra-high wear resistance, making it widely used in high-end PDC bits, such as shock-absorbing cutter, Center cutter, gauge cutter, etc.

|

VTL |  |

|

Impact(Dye checking) |  |

|

C-Scan |  |

|

X-Ray |  |

High Thermal Stability: Withstands extreme temperatures in polycrystalline diamond compact drill bits.

Superior Wear Resistance: Ensures longevity for polycrystalline diamond cutting tools.

Strong Corrosion Resistance: Ideal for harsh environments.

Excellent Conductivity: Supports heat dissipation in semiconductor applications.

Low Thermal Expansion: Maintains precision in PDC drill bits and polycrystalline diamond cutting tools.

E-Grind's PDC cutters for sale are versatile, serving a wide range of industries:

Oil and Gas Drilling: Our polycrystalline diamond compact bits and PDC core bits excel in tough geological formations, enhancing drilling efficiency.

Mining: Polycrystalline drill bits for sale provide precision and durability for hard-rock mining.

Electronics: Diamond powder abrasives with high thermal conductivity and electrical insulation are used as heat sinks for semiconductor devices.

Construction: Cutter PDC solutions deliver robust performance for cutting and grinding concrete and stone.

With over 50 years of experience, E-Grind stands out among diamond dust suppliers for our commitment to quality and innovation:

Advanced Manufacturing: State-of-the-art facilities ensure consistent polycrystalline diamond composites.

Rigorous Quality Control: Every PDC cutter undergoes strict ISO 9001-compliant testing, with detailed test reports included in each shipment.

Traceable Production: Every lot of our polycrystalline diamond compact bits is traceable, ensuring accountability.

Customer-Centric Approach: We prioritize 100% customer satisfaction with tailored polycrystalline diamond cutting tools and responsive service.

Global Trust: E-Grind is a reliable synthetic diamond powder supplier, serving industries worldwide.